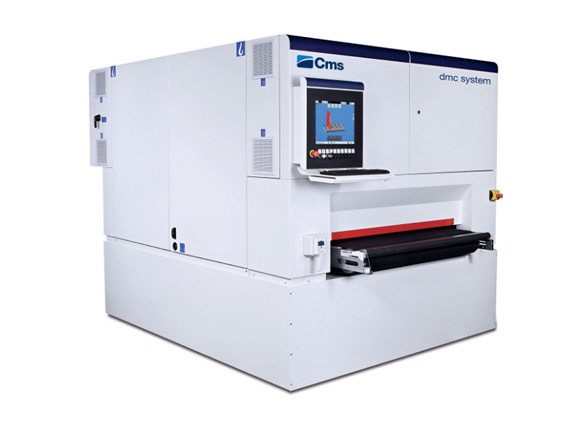

CMS DMC Metal System Dry deburring finishing machine for metals

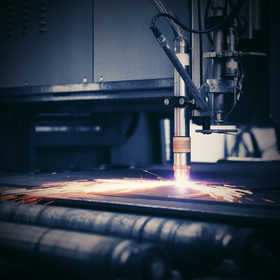

Represents a heavy-duty solution dedicated to the medium and large end user, as well as dedicated contractors, who are required to combine productivity, reliability and flexibility due to the ever changing work orders. In a single pass the machine is able to: eliminate any burr produced by the cutting process efficiently remove sharp edges all while creating a radius deburr and radius holes of small dimensions efficiently removes oxide generated while cutting, whether from the outer perimeter of the piece or the inner circumference of the hole

- operating unit with large diameter contact roller

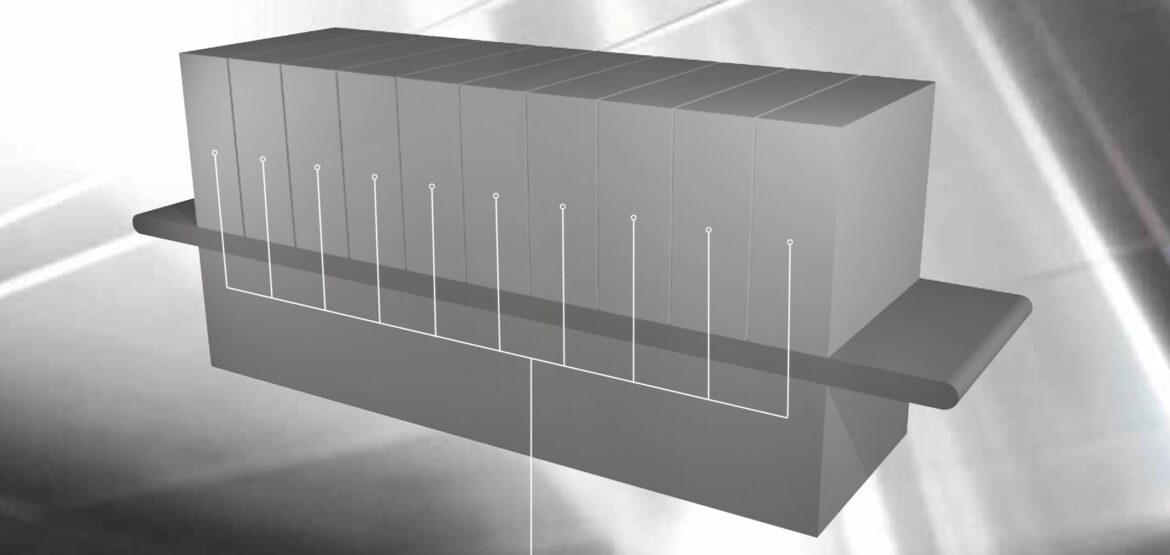

- planetary unit equipped with rotating disc brushes

- oscillating unit equipped with rotating disc brushes

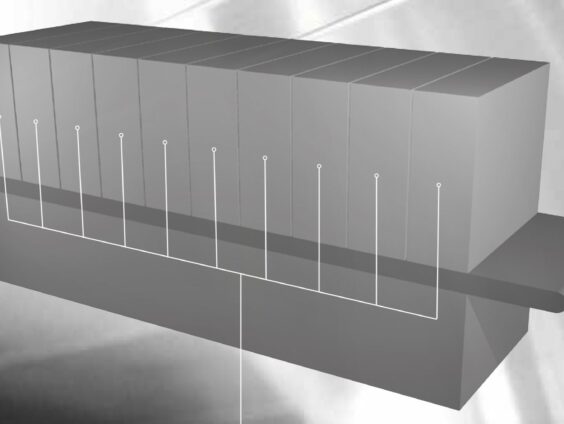

- vacuum table for processing small pieces, with in-built electric fan located in the machine frame

- working table at fixed height from floor for either stand alone or to be inserted in through-feed automatic lines

- machine controlled by “Hydra PC” with 17” touch-screen

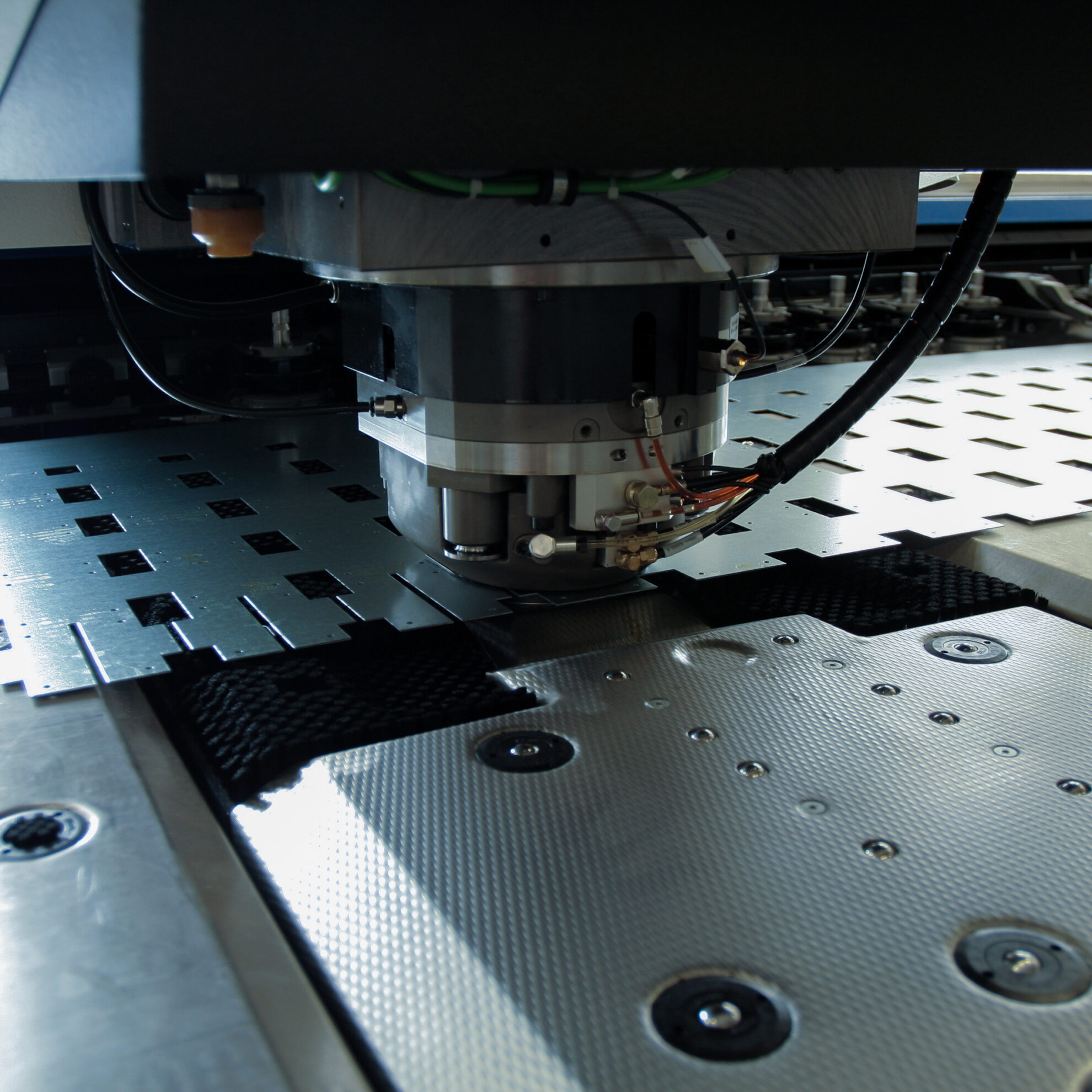

Excellent results for deburring, oxide removal and producing non-directional scratch thanks to the exclusive planetary unit which uses a gear box transmission that allows for independent speed rotation control of the brush discs as well as the planetary main discs.

Quick change-over time for the replacement of the brush discs thanks to the quick disconnect spindle shaft system that allows for a fast and easy set-up of the machine for any type of application while allowing for the maximum safety due to the locking system.

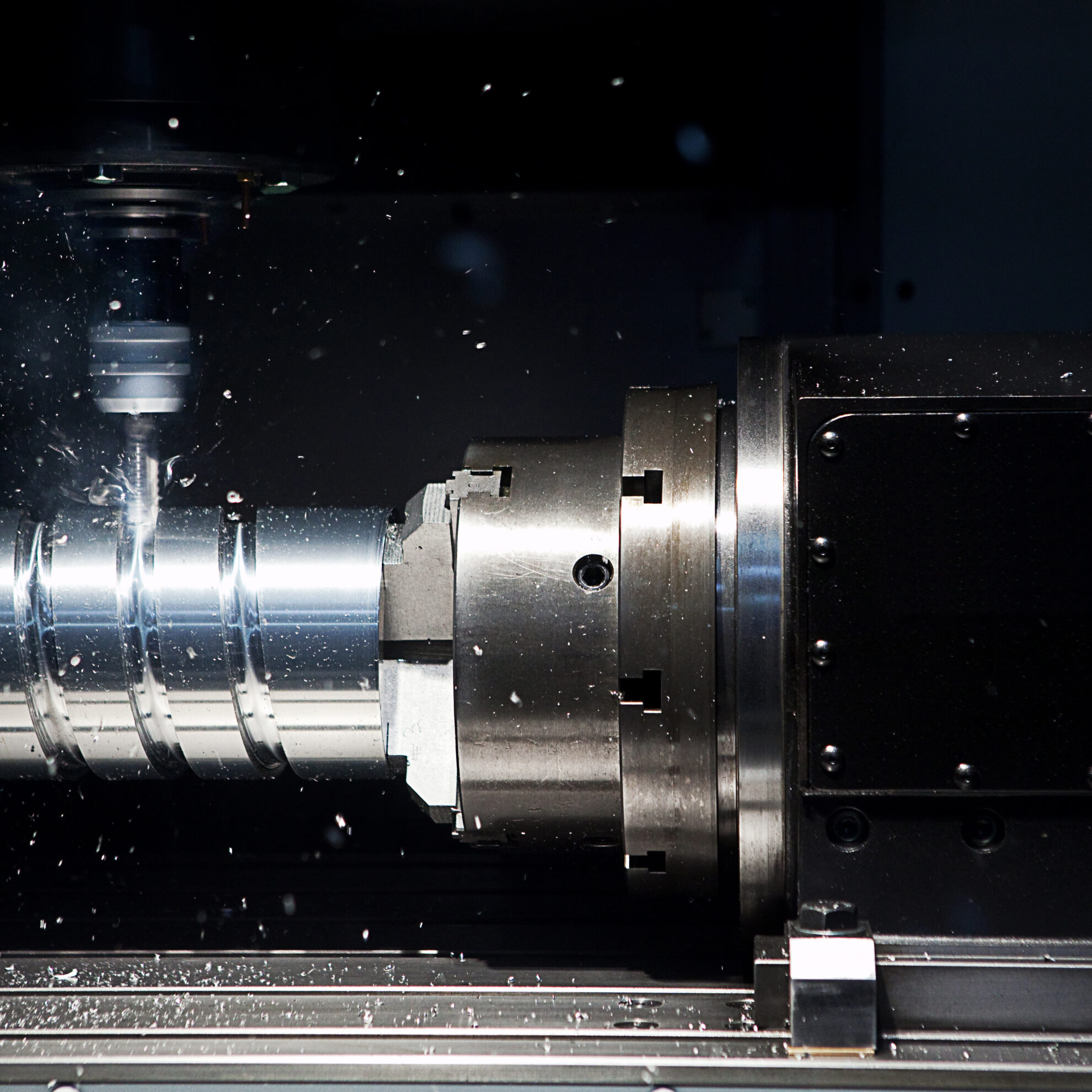

Extremely reliable and noiseless motor power transmission, even during the most extreme processing conditions, thanks to the multi-grooved Poli-V belts along with the self-tensioning belt device.

| Technical data | ||

| Type of processing | dry | |

| Working width | mm | 1350 |

| Min/Max working thickness | mm | 0,6 ÷ 170 |

| Abrasive belt width | mm | 1370 |

| Abrasive belt length | mm | 2620 |

| Working table height (from floor) | mm | 900 |