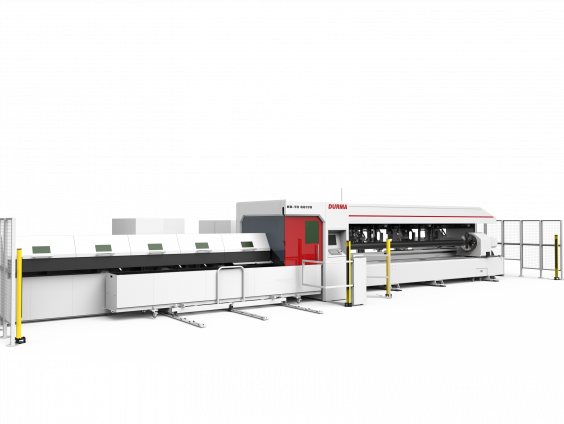

Vamzdžių lazerinio pjovimo staklės HD-TC Durma

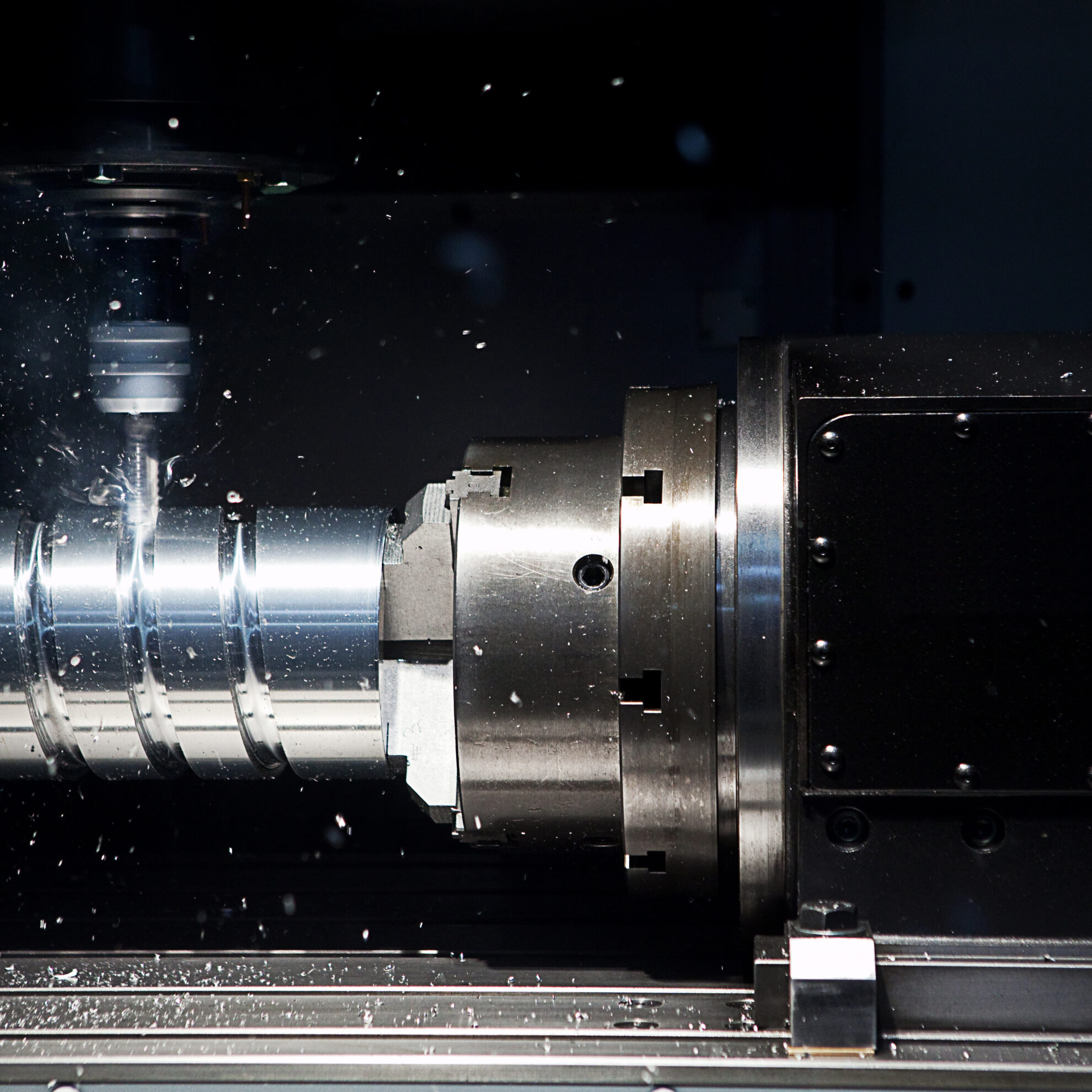

Vamzdžių lazerinis pjaustytuvas specialiai sukurtas įmonėms, kurios vertina aukštos kokybės vamzdžių (iki 220 mm skersmens) ir profilių pjovimą. Dėl iki 3 kW pjovimo galios lazeriu galima pjauti nuo 0,8 mm iki 10 mm storio vamzdžius ir profilius. Visiškai automatinis pakrovimas ir iškrovimas reikalauja mažiau pastangų ir taupo operatoriaus laiką. Judančias ašis suka priežiūros nereikalaujantys, dinamiški ir didelio našumo kintamosios srovės servo varikliai. Lazerinio pjovimo metu susidarančias dulkes į dulkių surinkimo filtrą įsiurbia siurbimo sistema.

Automatinė vamzdžių ir profilių padavimo sistema skirta sutrumpinti medžiagos paruošimo laiką, o automatinė vamzdžių ir profilių išvežimo sistema surenka nupjautą medžiagą nesustabdžius mašinos. Dėl kompaktiškos vamzdžių lazerio konstrukcijos visoms vamzdžių ir profilių įdėjimo / pjaustymo / ištraukimo operacijoms atlikti reikia mažiau vietos ir mažiau apdorojimo. HD-TC vamzdžių lazerinis pjaustytuvas išsiskiria greičiu, aukštos kokybės komponentais, efektyvumu ir pramoniniu dizainu.

HD-TC vamzdžių lazerinio pjaustymo stendas gali būti naudojamas įvairiose pramonės šakose, pavyzdžiui, automobilių, baldų, lentynų ir mašinų, statybų, žemės ūkio technikos ir plieno konstrukcijų gamyboje. Vamzdžiai ir profiliai plačiai naudojami daugelyje sektorių. Tokius procesus, kaip geometrinių formų pjaustymas, lengva atlikti. Lazerinės technologijos naudojimas vamzdžiams ir profiliams pjauti suteikia galimybę kurti estetiškus ir lanksčius dizainus.

Kokie yra „Durma HD-TC” vamzdžių lazerio privalumai?

- Patogus naudoti

Durma HD-TC vamzdžių lazeris buvo specialiai sukurtas atsižvelgiant į naudotojo patogumą. Jo automatizuota darbo eiga taupo jūsų laiką. Dėl ergonomiškos konstrukcijos juo lengva naudotis. - Efektyvus energijos vartojimas

Durma HD-TC vamzdžių lazerinis pjaustytuvas sukurtas atsižvelgiant į energijos vartojimo efektyvumą. Jo pažangi technologija ir dizainas optimizuoti taip, kad taupytų vietą ir energiją. Įrenginys yra greitas, ergonomiškas ir paprastas naudoti. Dėl pažangios technologijos mašinos eksploatavimo sąnaudos yra nedidelės. - Patikimas

Durma technologija sukurta siekiant tikslių rezultatų. Durma vamzdžių lazeris HD-TC yra patvarus ir patikimas, todėl tarnaus daugelį metų. Tiksli technologija užtikrina patikimus rezultatus.

Galima įsigyti du skirtingus įrenginius:

Durma HD-TC 60170 (maksimalus skersmuo 170 mm, kvadrato maksimalus skersmuo 120 mm, stačiakampio 150*100 mm).

Durma HD-TC 60220 (didžiausias skersmuo 220 mm, kvadratas 160 mm, stačiakampis 200*100 mm).

Mažos veiklos sąnaudos

Mažas energijos suvartojimas

Mažos išlaidos vienam komponentui

Optimalus židinio atstumas visoms storio vertėms

Techninės priežiūros nereikalaujantis veikimas

Kompaktiška konstrukcija, greitas montavimas

Tvirta korpuso konstrukcija, didelis patvarumas

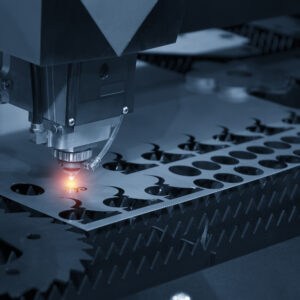

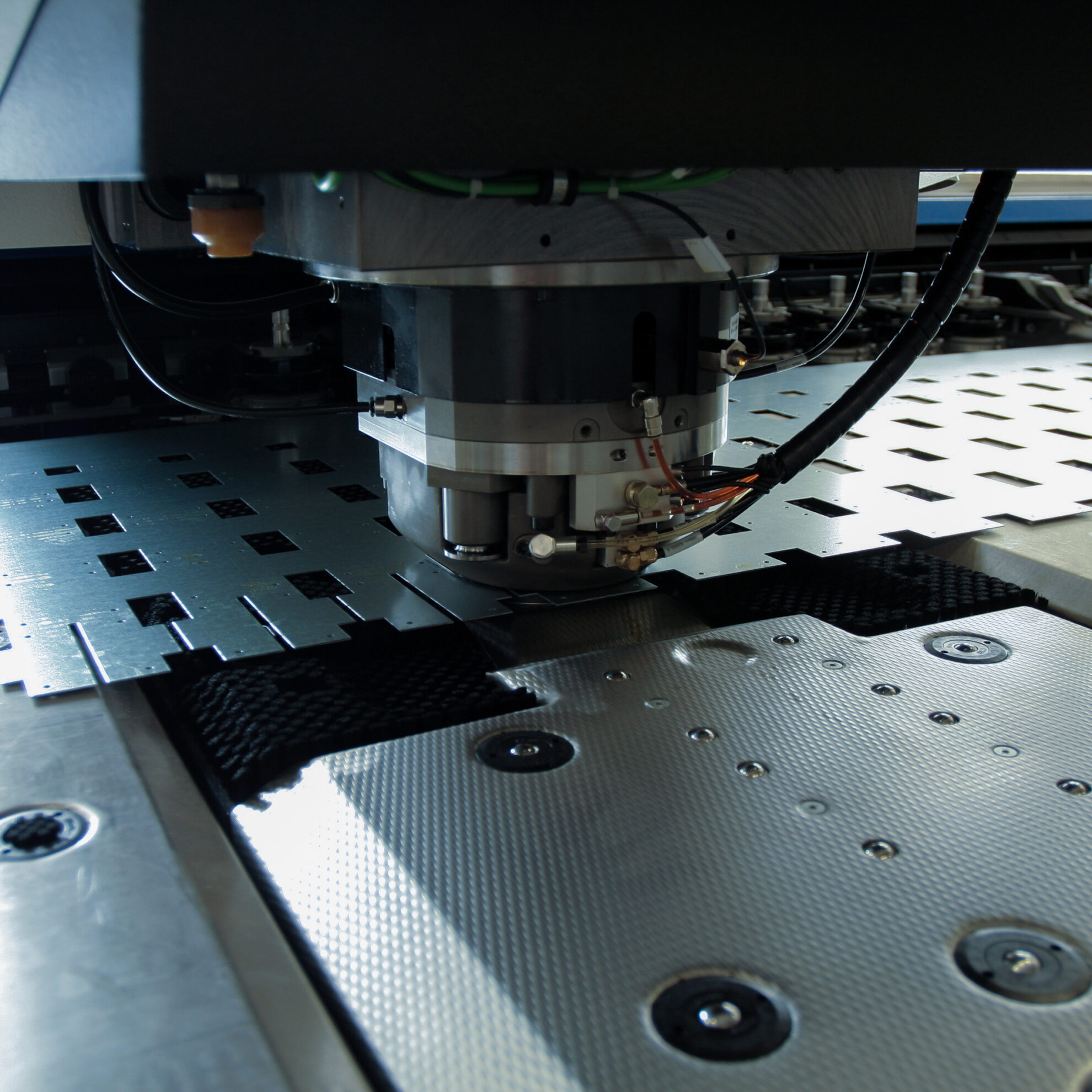

Lazerinio pjovimo galvutė

„ProCutter” siūlo išsamų sprendimą, skirtą plonų ir vidutinio storio medžiagų pjovimui lazeriu. Naudojant liepsninį pjovimą galima apdoroti storesnes medžiagas, išlaikant aukštus kokybės standartus.

Automatinė įkrovimo sistema

Profiliai vienas po kito iš krūvos perkeliami į perkėlimo grandinę, sistema perkelia profilį į viršų, griebtuvai suima profilį ir perkelia jį į kasetės ašį, kasetė laiko profilį.

Profilio ilgio matavimas

Profilio ilgiui matuoti ir duomenims į sistemą perduoti naudojamas servo variklis.

Vamzdžių tvarkymo sistema

Vamzdžių perkėlimo sistema užtikrina, kad vamzdžiai pjovimo linijoje būtų nukreipiami į tinkamą padėtį.

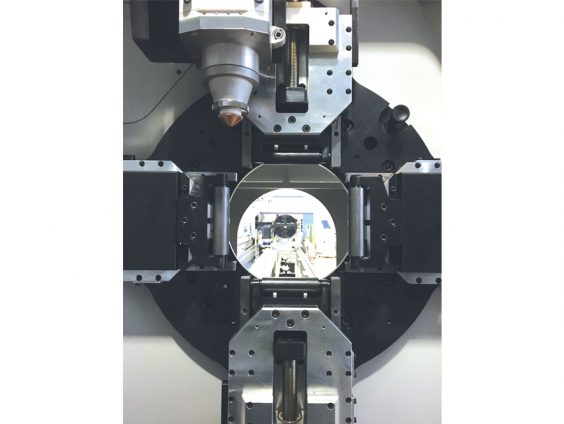

Hidraulinis profilio laikiklis

Leidžia laikyti įvairius profilius naudojant 4 spaustuvus, veikiančius nepriklausomai 2+2 principu. Hidraulinis slėgis automatiškai reguliuojamas atsižvelgiant į profilio medžiagos storį.

Grandinės tvirtinimo sistema

Grandinės laikymo sistema leidžia krauti nerūdijančio plieno, aliuminio, žalvario ir kt. vamzdžius jų nesubraižant.

Z ašis

Leidžia greičiau pjauti dėl didelio dinaminio našumo. Automatinio fokusavimo lazerinė galvutė sutrumpina pjovimo laiką pirminio paruošimo etape.

Automatinė įkrovos suėmimo sistema

Iš pakrovimo įrenginio atvežti vamzdžiai automatiškai perkeliami į pjovimo zoną ir centruojami.

Profilių palaikymo sistema

4 atraminės rankenos su servo varikliais išlaiko pakrovimą tame pačiame lygyje kaip ir hidraulinė kasetė. Kai hidraulinė kasetė perkelia profilį išilgai X1 ašies, atraminės rankenos viena po kitos užsidaro, kad atsidarytų hidraulinės kasetės priekis.

Apsaugos nuo purslų sistema

Apsaugos nuo purslų sistema naudojama tam, kad ant pjovimo briaunos susidaręs šlakas nepriliptų prie porinio profilio paviršiaus. Prie vidinio profilio paviršiaus prilipę įbrėžimai pablogina pjūvio kokybę ir dėl to reikia valyti vidinį detalių paviršių. Apsaugos nuo purslų sistema padeda išvengti visų šių problemų.

Automatinė dozavimo sistema

Išleidimo įrenginio atraminio mechanizmo aukštį valdo servovariklis, pjovimo metu profilis yra atremiamas.

Galimos 4 m ir 6 m versijos.

Galimi priekiniai ir galiniai variantai.

Iškrovimo stalas gali išimti nupjautus vamzdžius iš kabinos savo įeinamuoju-išeinamuoju judesiu.

Siūlių aptikimo jutiklis

HDTC mašinose įrengtas siūlės aptikimo jutiklis aptinka vamzdžio paviršių su siūle.

kraunant į mašiną ir leidžia operatoriui pasukti pjovimo angas bet kokiu kampu.

Centravimo sistema su lazeriniais jutikliais

Neseniai HDTC staklėse įdiegta centravimo lazeriniu jutikliu funkcija leidžia pjovimo metu arba prieš pjovimą jutikliais patikrinti profilio dydį ir nelygią struktūrą, kad būtų užtikrinta, jog pjaunami vidiniai kontūrai yra tinkamai centruoti.

| Vamzdžių pjovimo techninės specifikacijos | |

| Didžiausias skersmuo (mm) | Ø170 |

| Maksimalus kvadratinio vamzdžio matmuo (mm) | 120×120 |

| Maksimalus stačiakampio formos vamzdžio matmuo (mm) | 150×100 |

| Min. Skersmuo (mm) | Ø20 (Ø12 Option) |

| Didž. Vamzdžio ilgis (mm) | 6500 |

| Min. Vamzdžio ilgis (automatiniam pakrovimui) | 3000 |

| Didž. Vamzdžio svoris (kg/m) | 37,5 |

| Maksimalus vamzdžio ilgis (pvz. Medžiagos storis (mm) (2 kW) | 8 |

| Min. Medžiagos storis (mm) | 0,8 |

| Automatinis pakrovimas | Yes |

| Automatinis iškrovimas | Yes |

| Pjovimo galvutė | 2D |

| Griebtuvo kiekis | 1 |

| Centravimo griebtuvas | Yes |

| Paskutinio pjūvio vamzdžio ilgis (mm) | 185 |

| Valdančiojo griebtuvo greitis (m/dk.) | 90 |

| Valdančiojo griebtuvo pagreitis (m/s²) | 10 |

| Tikslumas (mm) | ±0,20 |

| Padėties nustatymo tikslumas (mm) | ±0,05 |

| Vamzdžių tipai | Pipe, Square, Rectangular, Eliptic H, C, U, L |