KOVOSVIT ROLLER 2800 CNC Special technologies

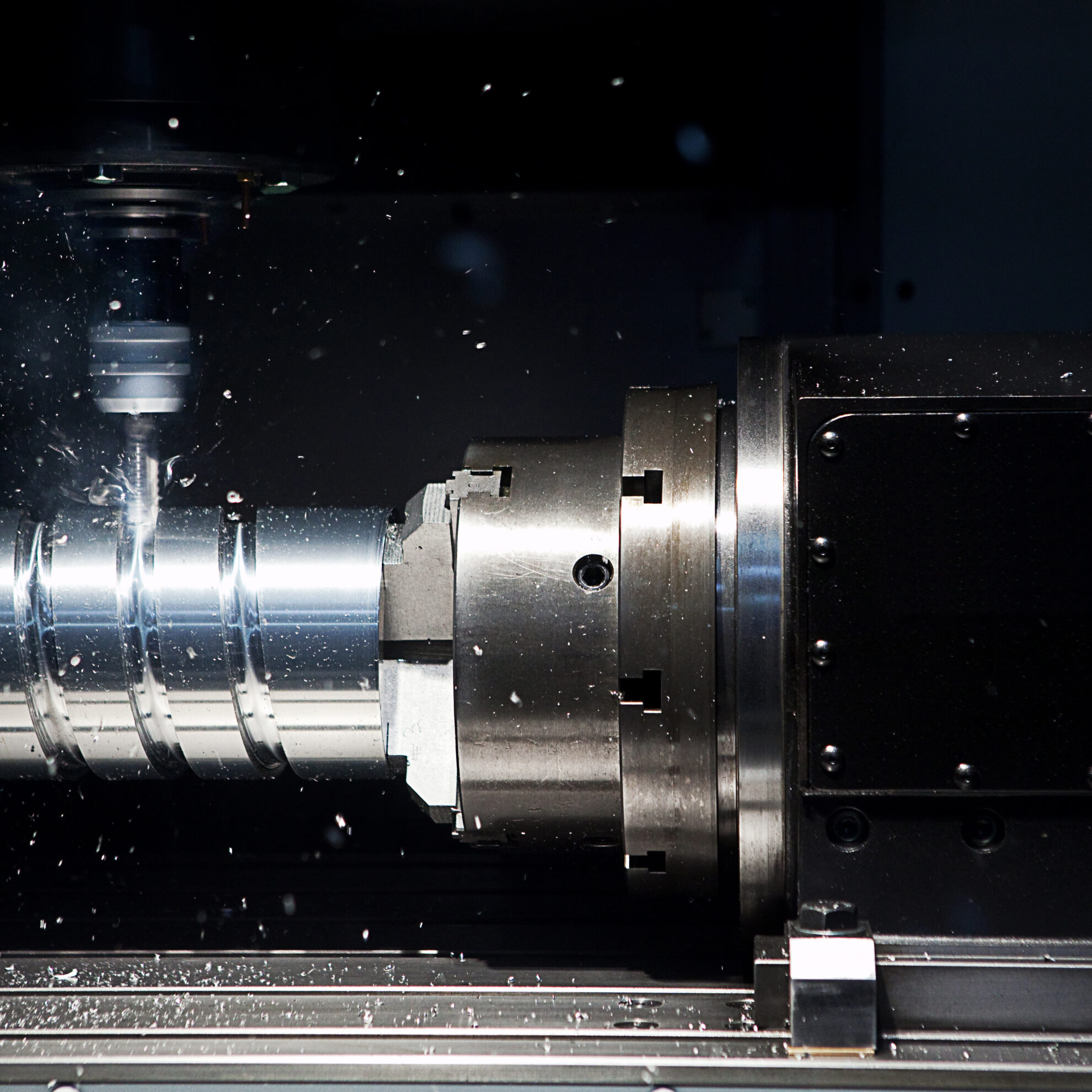

The special ROLLER 2800 CNC is the skeleton of the machine

and is derived from the standard MASTURN 70/3000 CNC lathe

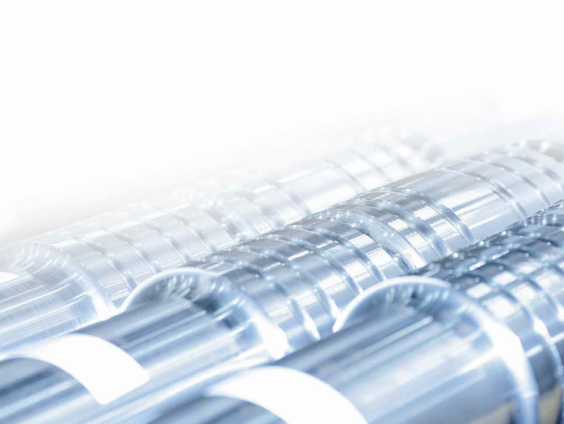

machine. The function is based on cold moulding technology:

the rolling of cylindrical, conical and transition radius areas of

shaft parts, i.e. vehicle axles. This function, along with others,

pre-determines the area of the use of the machine for the

specialized production of parts for use in surface fi xation

technology in a perpendicular direction of the rolling tool to the

surface of the material by means of a mechanism for tilting axis

B by the CNC system.

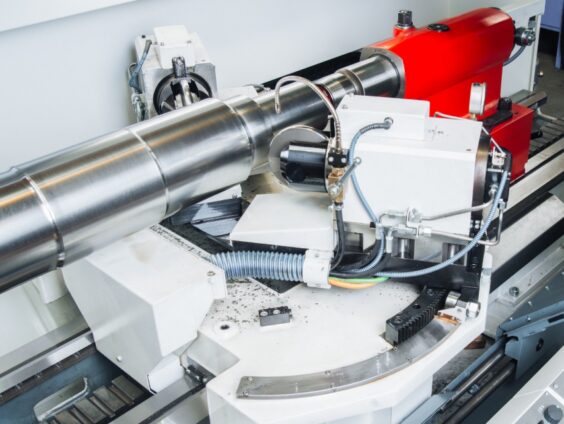

Form rolling equipment is located on the longitudinal saddle.

The saddle moves by means of a CNC controlled axis Z on the

bed of the machine in a longitudinal direction. The movement

in axis X is performed hydraulically by two opposite located

tailstock sleeves for the rolling heads, into which the rolling

tools are clamped. Fluent changes to pressure on the rolling

tools can be changed in the program during the working cycle.

The system enables the indirect independent measurement of

the rolling force and the recording and archiving of data from

the rolling process.

The arrestment of turning the rolling heads in the respective

position is ensured by a drive using self-locking worm gears.

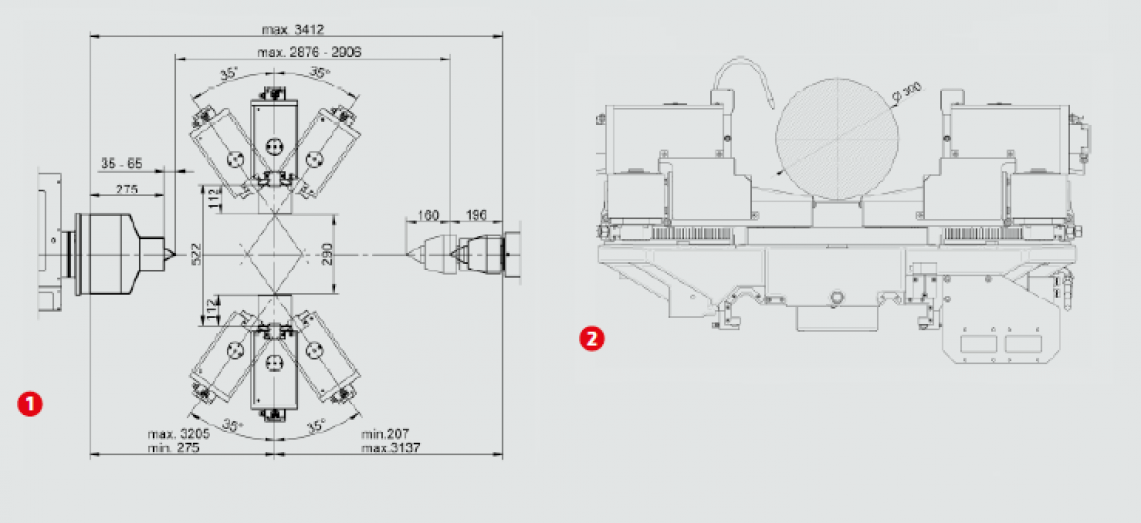

Swing dia. without using of tilting B-axes: 300 mm

Max. power of multi-roller without using of tilting B-axes: 50 kN

Max. workpiece weight: 1 000 Kg

Output S1: 11 kW

Working space lighting

Röhm 116 Mk6 (604H) movable centre

Calibrating load gauge

Adaptor into spindle Metric 112/Mo 6

Carrier

Lubrication of pulleys

Tube for lubrication oil for rolling oil

Tool kit

Accompanying documentation

The machine is equipped in standard with SIEMENS 840 D system

Lifting equipment 3000

Switch board cooling – air-condition

Adapter

Rolling holder (2 pc set)

Pulleys on request (2 pc set)

Remote diagnostics

Special movable centre

| TECHNICAL DATA | Roller 2800 CNC | |

| Geometric and operating accuracy | ISO 1708 | |

| Swing dia. without using of tilting B-axes | mm | 300 |

| Swing dia. with using of tilting B-axes to ± 30° | mm | 280 |

| Swing dia. with using of tilting B-axes to ± 35° | mm | 250 |

| Tailstock sleeve travel of multi-roller headstock | mm | 112 |

| Range of multi-roller power | kN | 1 – 50 |

| Max. power of multi-roller with using of tilting B-axes (B = ± 35°) | kN | 20 |

| Max. power of multi-roller without using of tilting B-axes (B = 0°) | kN | 50 |

| Distance between centres | mm | 2876 |

| Max. workpiece weight | kg | 1000 |

| Operating spindle | ||

| Nose of spindle (DIN 55027, 55029) | – | B11/C11 |

| Spindle bore | mm | 106 |

| Spindle taper – metric | mm | 112 |

| Control system | ||

| SIEMENS SINUMERIK | – | 840D |

| Main drive | ||

| Drive motor output (S1) | kW | 11 |

| Max. spindle torque (S1) | Nm | 297,5 |

| Spindle speed range | min-1 | 0-400 |

| Axis B | ||

| Ratio of worm-gear unit | – | 01:40 |

| Ratio of spur gearing of tilting mechanism | – | 01:12 |

| Tilting range | ° | ± 35 |

| Rapid traverse | min-1 | 0-400 |

| Axis Z | ||

| Ball screw – dia. / increase | mm | 50/10 |

| Travel | mm | 2876 |

| Rapid traverse | m/min | 10 |

| Max. feed force | kN | 20 |

| Repeatability of positioning | mm | 0,015 |

| Tailstock | ||

| Tailstock sleeve dia. | mm | 115 |

| Tailstock sleeve travel | mm | 160 |

| Sleeve taper | MORSE | 6 |

| Hydraulic aggregate | ||

| Hydraulic oil volume | l | 10 |

| Operating pressure of pump | bar | 110 |

| Nominal capacity of pump | l/min | 11 |

| Nominal motor output | kW | 3 |

| Lubrication of multi-roller tools | ||

| Nominal pressure of pump | bar | 3 |

| Nominal capacity of pump | l/min | 0,9 |

| Tank capacity | l | 32 |

| Pump motor rating | kW | 0,05 |

| Machine dimensions | ||

| Length × width × height | mm | 4000 x 1815 x 1863 |

| Machine weight | kg | 6200 |

| Max. total machine input | ||

| Machine input | kVA | 30 |