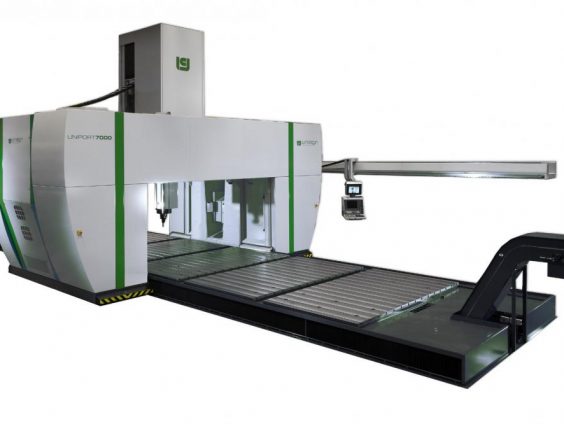

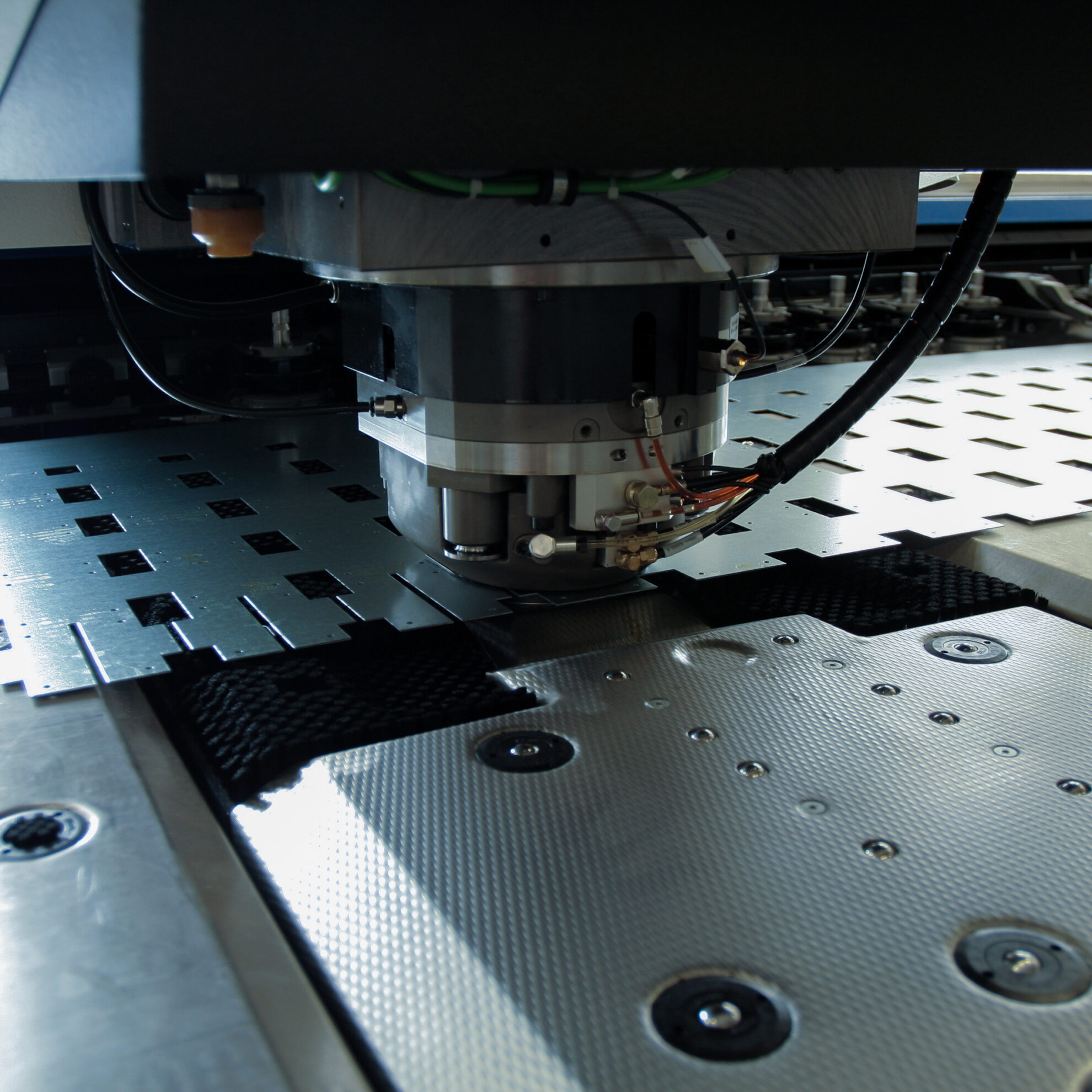

Unisign uniport 7000 Flexible Portal CNC Machining Centre

Flexible and economic The Uniport 7000 is the economic solution to flexible manufacturing. This high-rail gantry machine with its travelling bridge and stationary table is our most flexible machine platform. It will perform 5-sided machining inside the component and has short changeover times and a large working envelope, making it a truly cost-effective production choice for a really wide range of applications. The innovative ‘box-in-box’ construction guarantees superb rigidity and very stable and accurate production processes.

One to the power of two

With its high capacity tool magazine and machining heads all ‘on board’, the Uniport 7000 is capable of extremly fast changeover times. Add component loading from the side – thanks to the accessible machine bed – and you’ll see why production times with this machine are really short, keeping productivity high.

High accuracy

The portal construction, with its guideways and drive system on both sides, provides real stability, while work-piece clamping is performed easily – mostly in the assembly orientation. This ensures a high level of accuracy. The wide choice of spindles and machining heads extends the flexibility of this machine enormously.

Fewer setups

The 5-sided machining, even inside the component, reduces the number of setups required in the Uniport 7000. And since the machine is built into the factory floor, it’s easy for operators to step onto the table to change clamps and workpieces.

Right angular indexing head

Universal indexing head

5-axes configuration

Carousel turning station

Raised guideways

Siemens / Heidenhain

| Work area | |

| X-axis | 6.000 – 24.000 + mm |

| Y-axis | 2.500 – 6.500 mm |

| Z-axis | 1.250 – 1.600 mm |

| Vertical clearance | 1.500 / 1.750 / 2.000 mm |

| Width between columns | 2.000 – 6.000 mm |

| Gear box driven spindle | 42/73 kW, 6.000 min-1, 1.600 Nm |

| Spindle | |

| Gear box driven spindle | 42/73 kW |

| 6.000 min-1 | |

| 1.600 Nm | |

| Various | |

| Tooling | |

| Taper size | HSK100A |

| Number of pockets | # 48-330 |

| Tool change time | 10 sec |

| Speed | |

| Rapid traverse | 40.000 mm/min |

| Feed Rate | 5 – 40.000 mm/min |