CMS Tecnocut Aquatec Waterjet Cutting Robots

A revolution in CMS Tecnocut product range: accuracy and reliability.

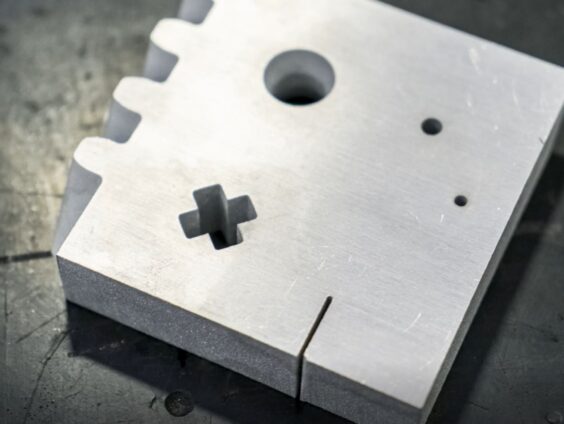

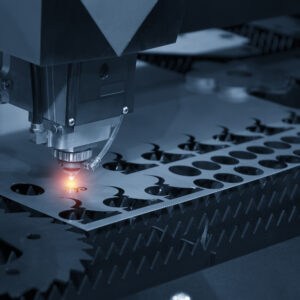

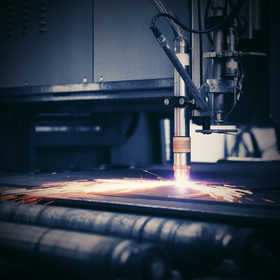

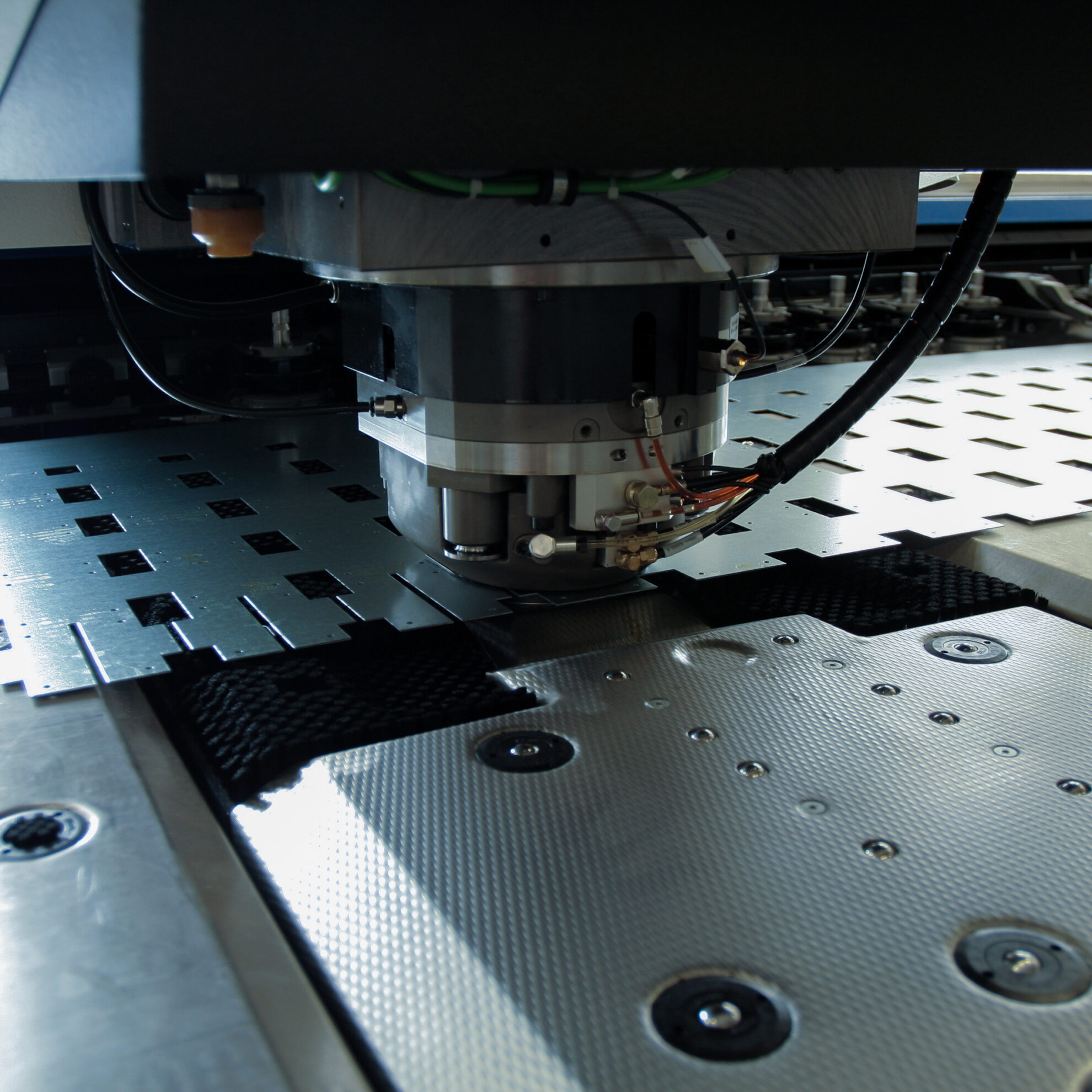

CMS Tecnocut introduces tecnocut aquatec, a groundbreaking new waterjet machine suitable for metals, advanced materials, stone and glass of any size and shape.

Advantages:

Modular structure: a wide range of configurations to suit any demand

Gantry structure with 30 mm helicoidal racks, providing high accuracy and reliability

New generation of cutting heads with an internal circuit for the abrasive, wholly designed and manufactured in CMS

Significant increase of the Z-axis stroke, up to 530 mm, to cut very high thicknesses

Customized solutions: a wide range of accessories allows to configure a machine tailored to the user demands

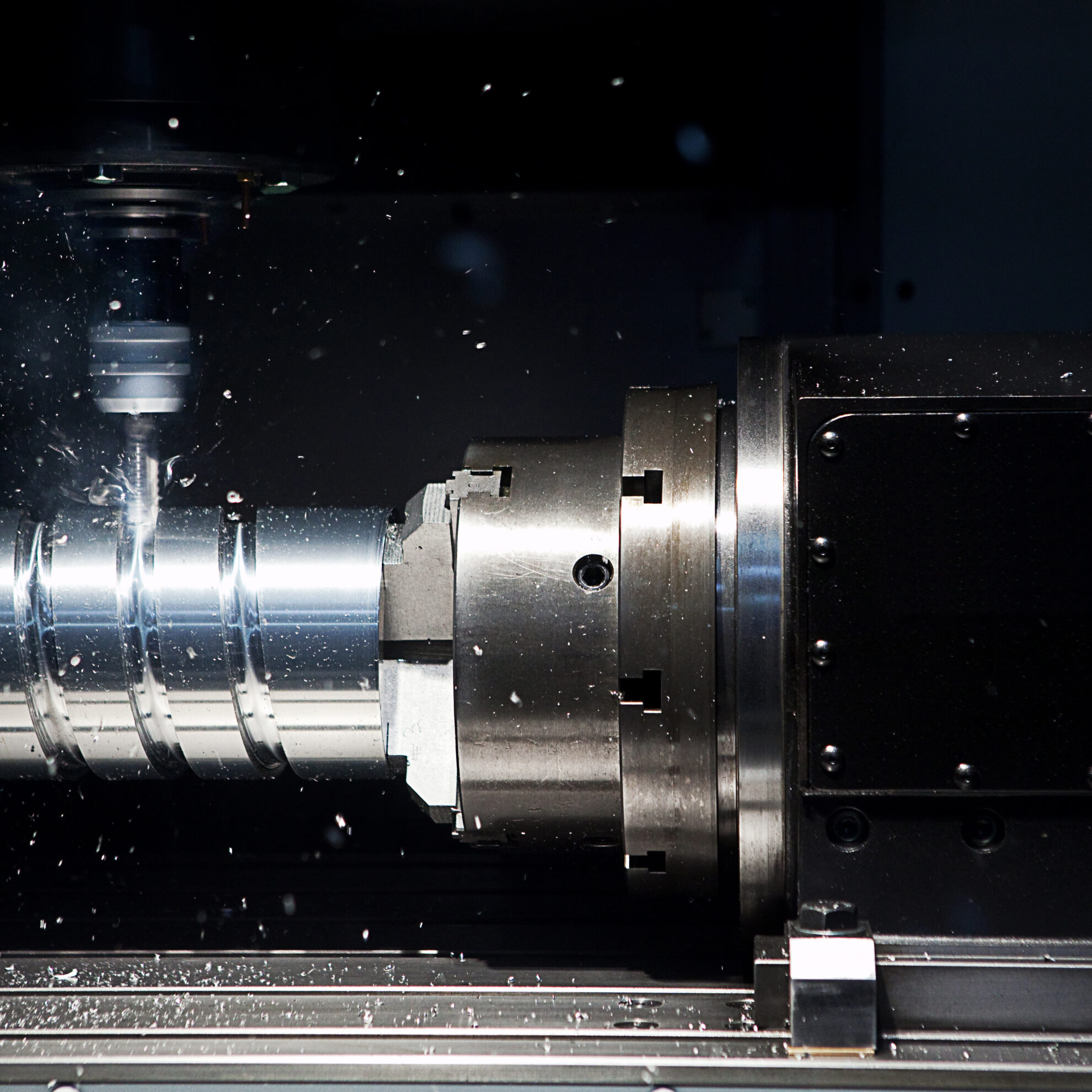

Tecnocut Aquatec is an advanced, versatile, high-performance abrasive waterjet cutting system, able to accommodate the most diverse production demands in different application fields, delivering highly accurate cuts. The machine consists of a mobile bridge moving along separate high-thickness steel supports, fastened to the floor and providing outstanding structural rigidity. This structure delivers high performances even by the most demanding tasks.

- the motions – including the one of the cutting head – are carried out by high precision tempered ground rack, driven by brushless motors

- steel guards and the polyurethane bellows protect all motion components from water and powders

- loading and unloading the material is fast and simple thanks to three open sides, as well as checking the cutting process. Moreover it allows to possibly install additional equipment to handle the material

| TECNOCUT AQUATECH: TECHNICAL DATA | ||||||

| MODEL | 2030 | 2040 | 2060 | 3060 | Rapid | Acceleration |

| X AXIS | 3800 mm | 2000mm | 4000mm | 6000mm | 54 m/min | 2 m/s² |

| Y AXIS | 2650 mm | 2000 mm | 2000 mm | 2000 mm | 54 m/min | 2 m/s² |

| Z AXIS | 530 mm | 530 mm | 530 mm | 530 mm | 12,6 m/min | 1 m/s² |

| B AXIS | ± 60° | ± 60° | ± 60° | ± 60° | 17200 °/min | 1450 °/s² |

| C AXIS | ± 340° | ± 340° | ± 340° | ± 340° | 13400 °/min | 850 °/s² |

| WORKABLE AREA | 2000 x 3000 mm | 2000 x 4000 mm | 2000 x 6000 mm | 3000 x 6000 mm | ||

| OVERALL DIMENSIONS | 5886 x 4039 mm without light barriers | 5886 x 4039 mm without light barriers | 7886 x 4039 mm without light barriers | 7886 x 5039 mm without light barriers | ||