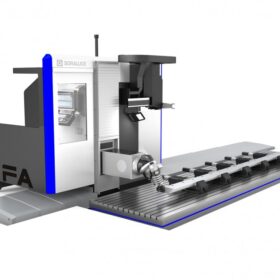

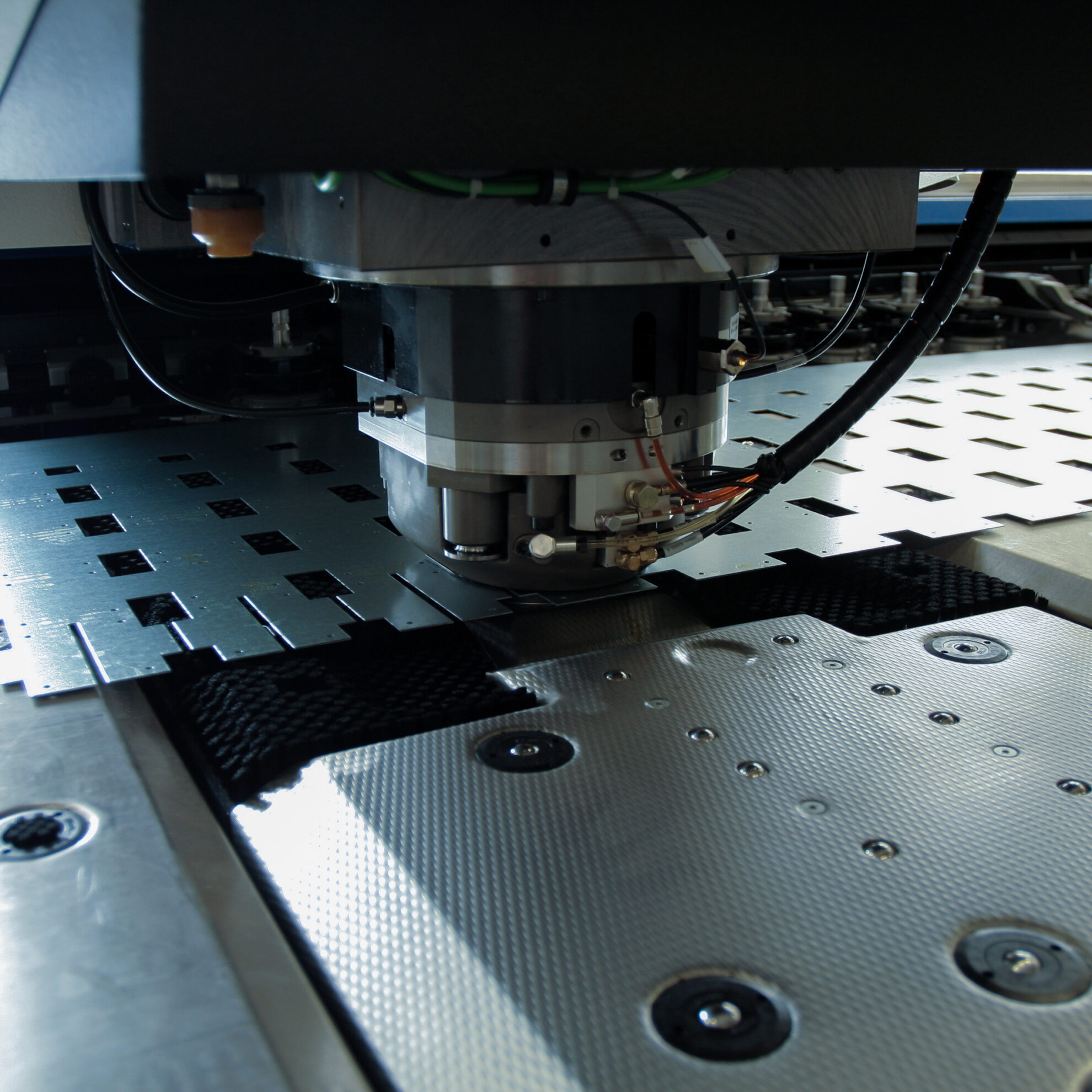

Durma SBT SERIES Swing Beam Shear

High technology standards, design and user-friendly interface SBT provides perfection with high standard safety, efficient solutions that strengthen your skills and add value to your company.

DURMA Shears have been manufactured since 1956 and have been installed and working in a wide variety of sheet metal cutting operations for many industries.

Years of experience has helped us develop durable, low distortion and precise cutting machines.

We have reduced the cutting angle to achieve straight precision and minimum twist tolerance.

Unique design and rigid body enable SBT series to provide perfect cutting quality and low cost solutions.

- Heavy duty St 44 steel construction & stress relieved frame

- User friendly CNC Touch screen control unit D-Touch 7

- Easy blade gap adustment

- Ball integrated front tables

- Ballscrew back gauge, 1000 mm & automatic swing-up

- Squaring arm with scale & T-Slot & tilting stop

- Support arms T-Slot & Tilting stop

- Illumination & shadow line1 mt flip-up finger guards

- Automatically pressure adjusted solid holddowns

- Top blades with 2 sides and Bottom blades with 4 sides Foot pedal

- High performance hydraulics & electronics components

- Automatic Swing-up back gauge

- Motorized blade gap adjustment

- Laser cutting line

- Light curtains for finger protection

- Pneumatic thin sheet support DURMA I

- Pneumatic thin sheet support DURMA IV

- Special throat depth

- Backgauge 1250 mm.

- support arms

- Special blades

- Oil coolant

- Oil Heater

- Adjustable angle stop 0-180°

- Control panel on opposite position

- Temperature measurement

- Overseas special packaging

| SBT Series | Cutting length | MS (450 N/mm²) | SS (700 N/mm²) | Throat Depth | Stroke per min. | Cutting Angle | Holddowns | Holddown Force | Back Gauge Range | Back Gauge Force | Back Gauge Speed | Motor Power | Oil Capacity | Front Arms | Tabla Height | Table Width | Table Length | Length | Width | Total Width | Height | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | 1/dak | ˚ | No | Ton | mm | kW | mm/sn. | kW | lt | Unit | mm | mm | mm | mm | mm | mm | mm | ~kg | |

| A | D | |||||||||||||||||||||

| 3006 | 3100 | 6 | 4 | 50 | 15 | 1˚30` | 16 | 14 | 1000 | 0,75 | 200 | 15 | 200 | 2 | 865 | 500 | 3515 | 4110 | 2200 | 3700 | 2100 | 7300 |

| 3010 | 3100 | 10 | 6 | 50 | 13 | 1˚30` | 16 | 22 | 1000 | 0,75 | 200 | 22 | 200 | 2 | 865 | 580 | 3515 | 4200 | 2250 | 3600 | 2100 | 9050 |

| 3013 | 3100 | 13 | 8 | 50 | 13 | 1˚45` | 16 | 37 | 1000 | 0,75 | 200 | 30 | 330 | 2 | 845 | 600 | 3550 | 4280 | 2300 | 3600 | 2350 | 11800 |

| 3016 | 3100 | 16 | 10 | 350 | 10 | 2˚ | 14 | 61 | 1000 | 0,75 | 200 | 37 | 410 | 2 | 818 | 550 | 3580 | 4550 | 2250 | 3825 | 2250 | 14580 |

| 3020 | 3100 | 20 | 13 | 350 | 6 | 2˚ | 14 | 77 | 1000 | 0,75 | 200 | 45 | 450 | 2 | 886 | 570 | 3670 | 4450 | 2260 | 3400 | 2450 | 20480 |

| 4006 | 4100 | 6 | 4 | 50 | 12 | 1˚30` | 20 | 17 | 1000 | 0,75 | 200 | 15 | 200 | 3 | 865 | 580 | 4510 | 5230 | 2300 | 3600 | 2150 | 11460 |

| 4013 | 4100 | 13 | 8 | 350 | 8 | 1˚45` | 18 | 62 | 1000 | 0,75 | 200 | 30 | 330 | 3 | 818 | 550 | 4520 | 5350 | 2250 | 3650 | 2250 | 16300 |