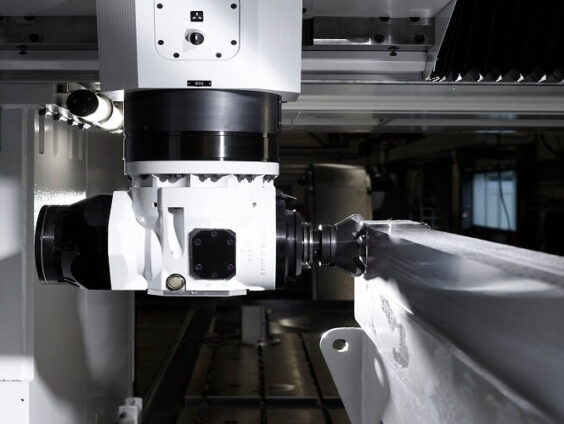

UNISIGN UNIPORT 6000 Large Portal CNC Machining Centre

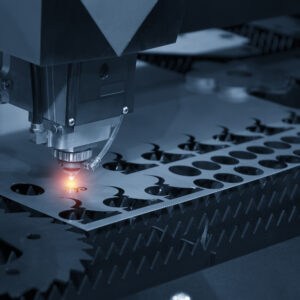

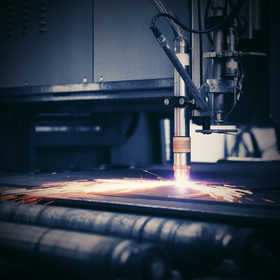

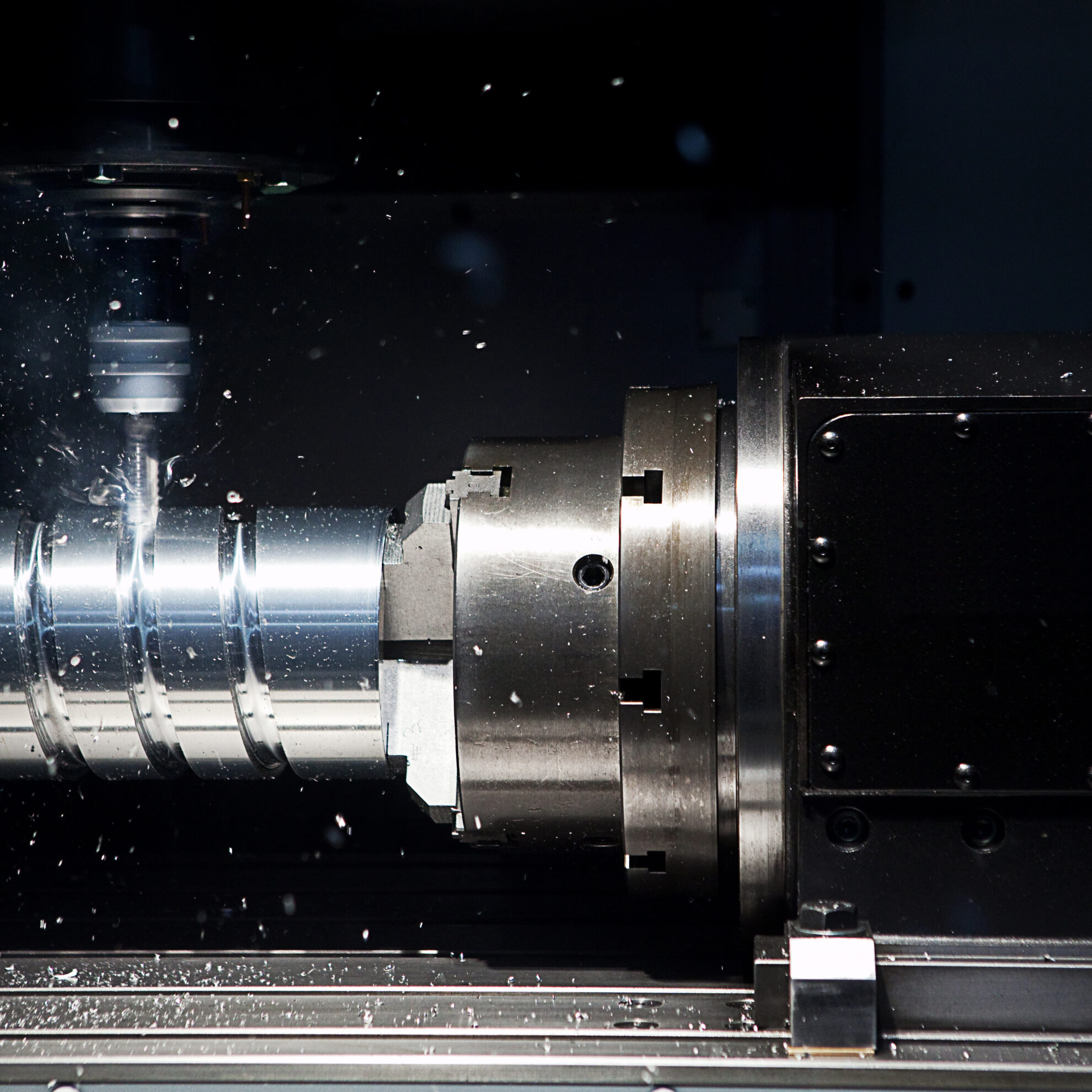

Powerful all-rounder The Uniport 6000 is the ideal choice for multi-sided manufacturing of large components in the most economical way. It is available in gantry configuration or as a moving table with pallet changer. The high vertical clearance and an optional carousel turning station address even the most challenging workpieces. The choice of machining heads enables milling, drilling, tapping, turning and even grinding and rolling – all in a single, small footprint machine.

Quick payback

The Uniport 6000 with its high-torque gearbox and a host of time-saving features is a truly productive machining centre. Able to handle multiple operations in a compact footprint, this high-uptime machine offers a really excellent ROI. Manufacturers agree that this machine is in a class of its own.

High usability

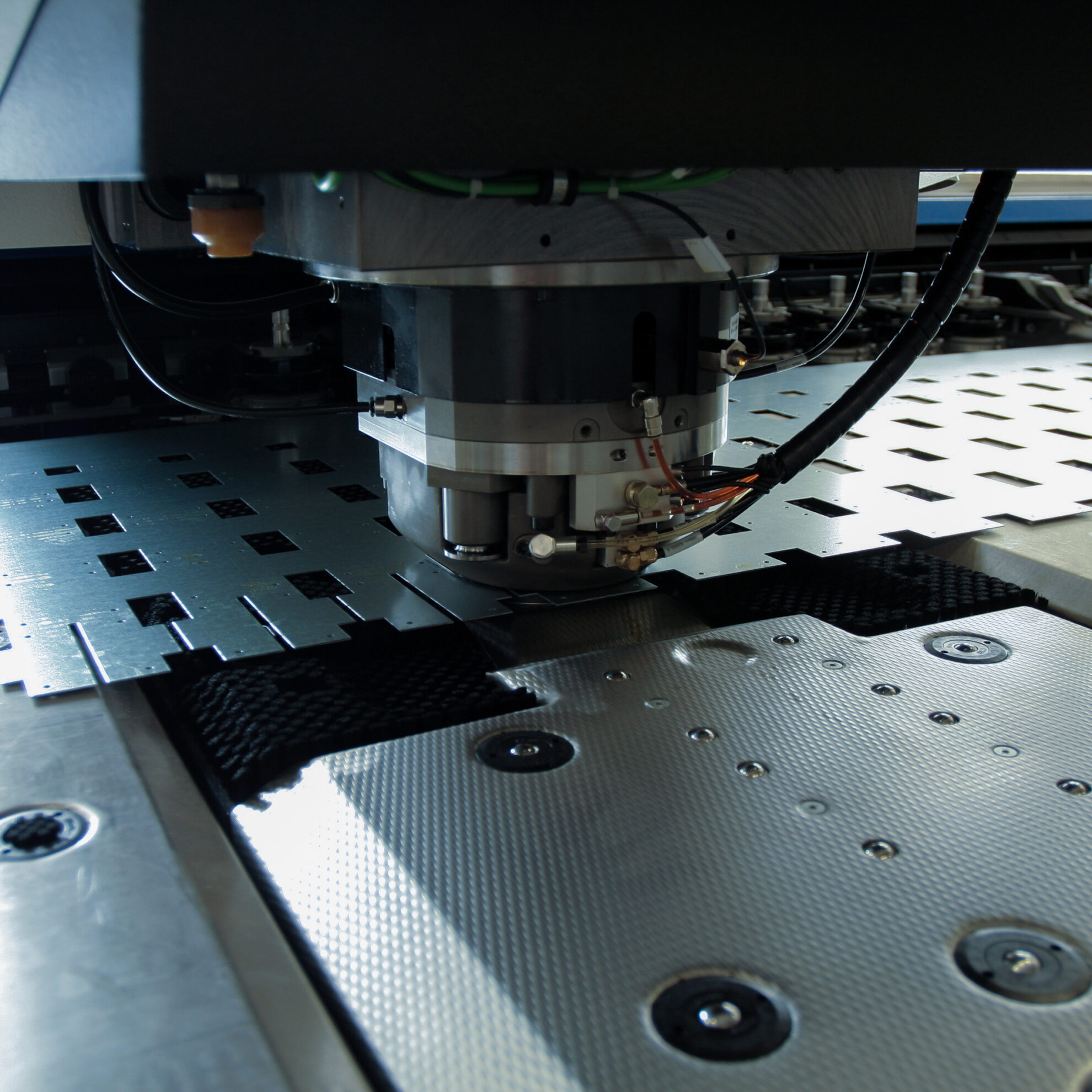

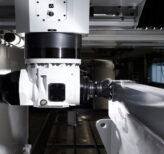

Featuring a powerful, gearbox-driven spindle with up to a 1000 Nm torque and a choice of right angle and universal heads, this machine can take on just about any large component challenge. With automatic exchange of heads and tools (up to 200 tool pockets!) and the option to integrate a carousel turning station in the machine bed, this machine is renowned for its high usability.

Easy access

When the Uniport 6000 machine is built into the factory floor, it’s easy for operators to step onto the table to change clamps and workpieces. The work area is flexible too, with the option to use the entire area for one large piece, or to adopt pendulum machining with the two stations separated by a screen.

| Work area | |

| X-axis | 4.000 – 20.000+ mm |

| Y-axis | 1.500 – 4.000 mm |

| Z-axis | 800 / 1.000 / 1.250 mm |

| Vertical clearance | 1.100 / 1.300 / 1.550 mm |

| Width between columns | 1.500 – 4.000 mm |

| Spindle | |

| Gear box driven spindle | 36/54 kW |

| 6.000 min-1 | |

| 720/1000 Nm | |

| Various | |

| Tooling | |

| Taper size | HSK100A / SK50 |

| Number of pockets | # 30-216 |

| Tool change time | 10 sec |

| Speed | |

| Rapid traverse | up to 36.000 mm/min |

| Feed Rate | 5 – up to 36.000 mm/min |