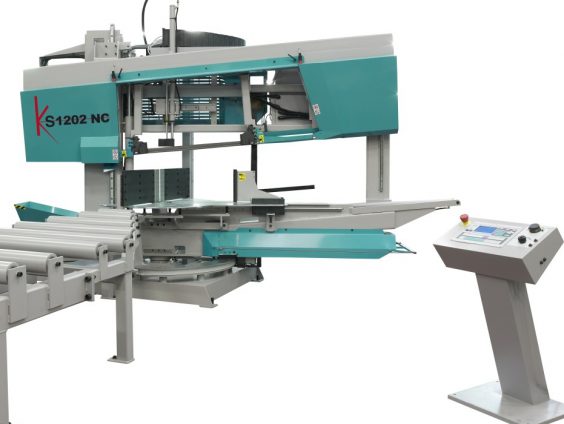

IMET KS 1202 NC INDUSTRY 4.0 READY* Semiautomatic twin column bandsaws

Semiautomatic twin column bandsaws with hydraulic lowering of the bow and motorized mitring by CNC control. Conceived and projected especially for cutting big profiles, beams, pipe and also solids. Possibility to make cuts with variable angle from 60° left to 60° right in automatic cycle.

The rotation of the machine is made with geared motor and linear encoder positioned at a high distance from the center of rotation for highest precision in the position with hydraulic locking of the rotation.

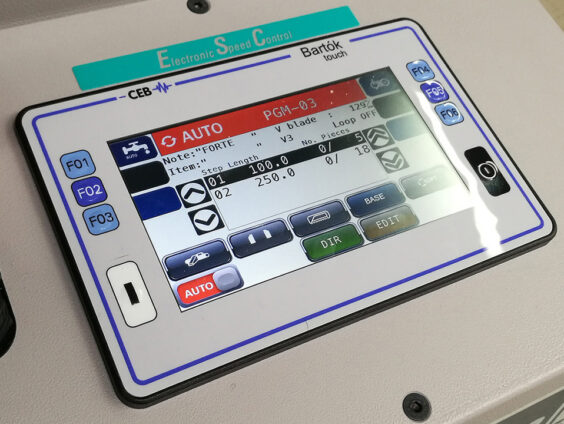

Automatic detection start/end cut points.

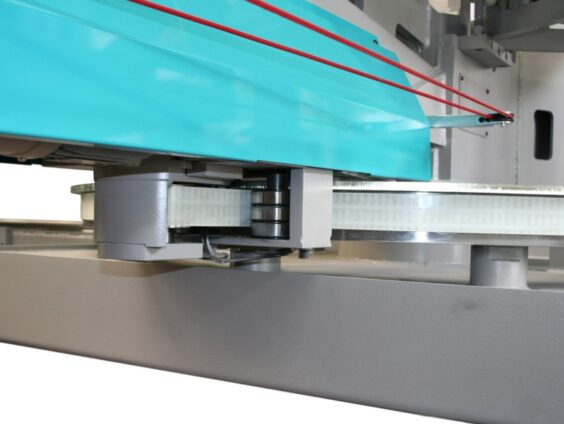

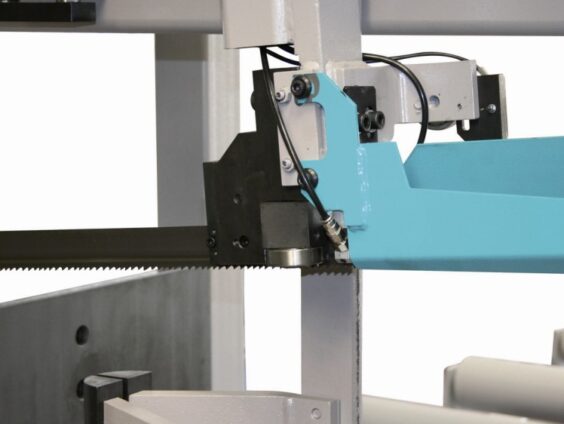

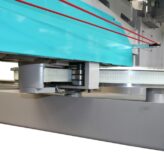

Against the common use the canted sawframe allows saw blade to freely and easily cut through the bottom of structural section without vibration,binding, or slowing down of sawing rates.

The steel welded arch with new design and big thickness section guarantees the absolute lack of vibration and noise.

The special section with inclined pulleys ensures a minor twist of the blade extending the life of the tool.

All movements of the sawing machine are on last generation recirculating ball screws guide.

“Clean cut” due to standard cooling system with minimal lubrication to cut long pipe and profile without any leakage of coolant.

It’s available also with manual rotation of the

bow and digital display to show the angle, easy stops at 0° and 45° left and right.

Cutting capacity at 90 °: Round 680 mm., square 640 mm. Rectangular 1250 x 600.

*The modem for Industry 4.0, teleservice and remote control is supplied as an optional.

| KS 1202 | ||

| Area angular cut | ° | 90 |

| Cutting capacity at 90°: round / square / rectangular | mm. | 680 / 640 / 820 x 610 |

| Cutting capacity at 90°: rectangular with cutting bundle | mm. | 800 x 350 |

| Blade dimensions | mm. | 7960 x 41 x 1.3 |

| Blade Motor Power | KW | 5.5 |

| Run of the feeder carriage (repeatable) | mm. | 1500 or 3000 |

| Feeder motor power | KW | 1.5 |

| Scrap end | mm. | 150 |

| Blade speed | mt/min. | 15 ÷ 100 |

| Motor hydraulic unit | KW | 1.5 |

| Tank Capacity of the hydraulic unit | Lt | 20 |

| Capacity coolant tank | Lt | 3 |

| Dimensions ( B x L x H ) | mm. | 5850 x 3600 x 2700 ( F 3000 ) |

| Height of the work-table | mm. | 820 |

| Weight | Kg | 4460 ( F 3000 ) |

| Minimum cuttable length | mm. | 30 |

| Type of functioning | semiautomatic/automatic CNC | |

| Suitable for cutting: | Steel / cast iron / high-strength steels | |