IMET SIRIO 370 AF-E Automatic, vertical column circular saw

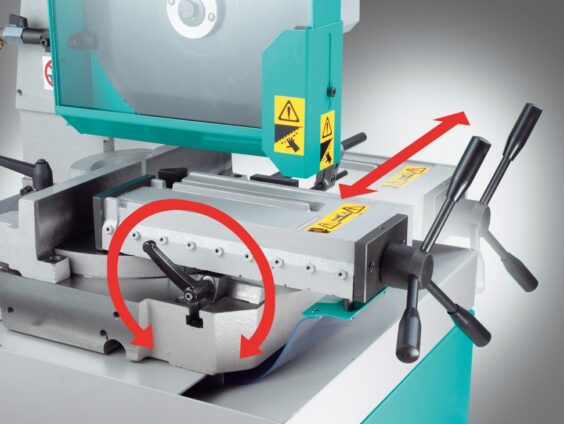

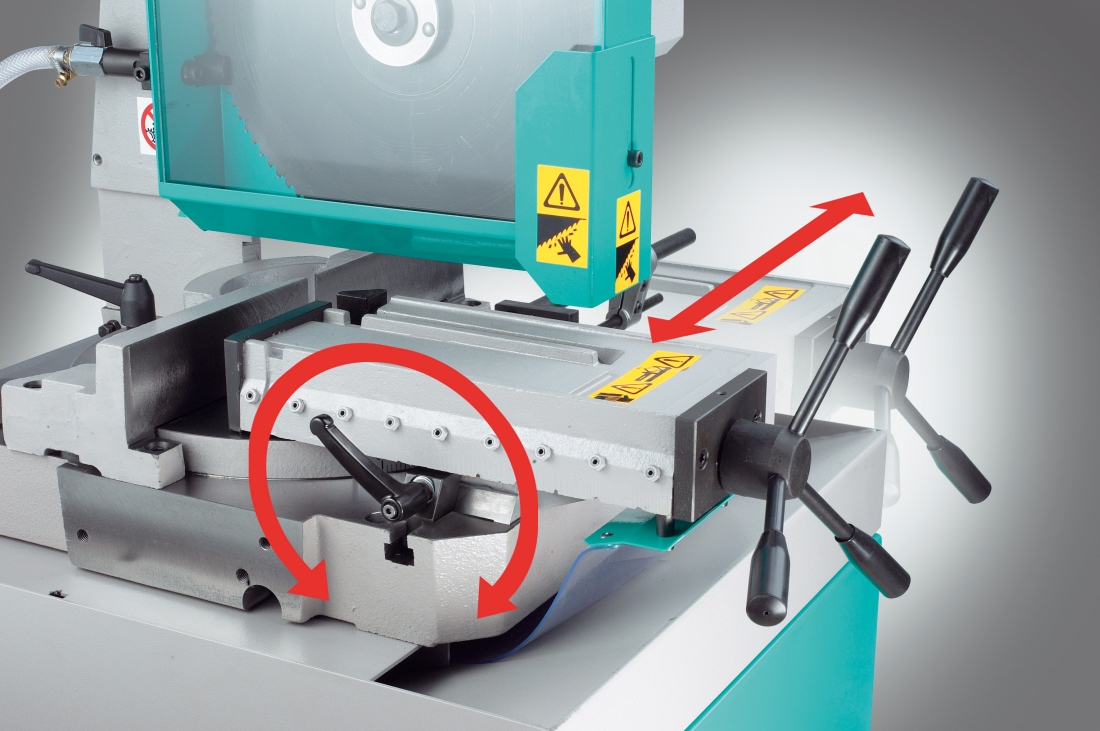

Automatic, vertical column circular saw; mitre cutting from 0° to 45° right (only semiautomatic cycle)and from 0° to 60° left.

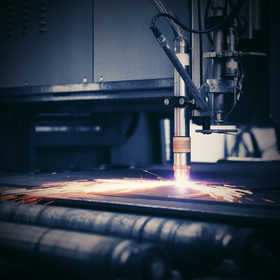

- Suited to cut high-resistance steel, the version with electronic Inverter widens the cutting possibilities, from stainless steel to brass and copper.

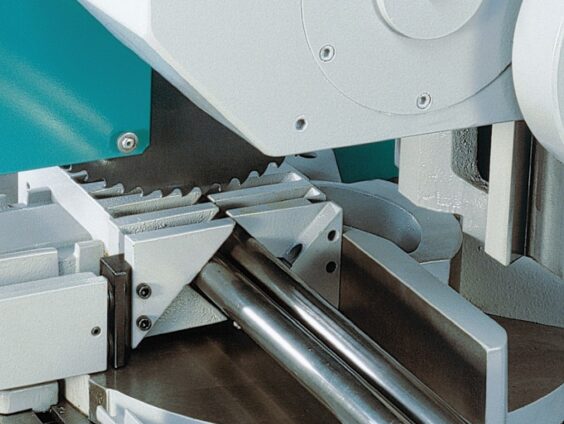

- Primary transmission with pulleys and cogged belt, final reduction in oil bath with big-size bronze crown gear.

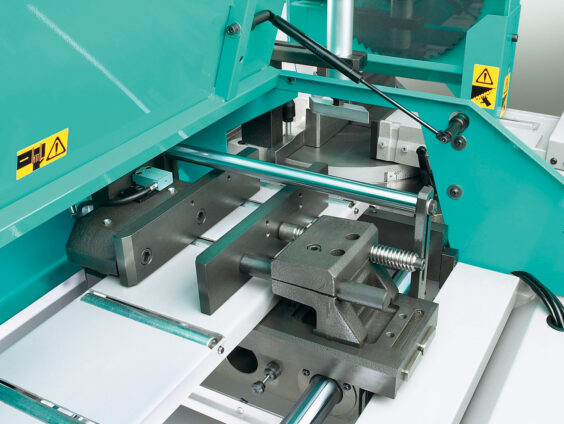

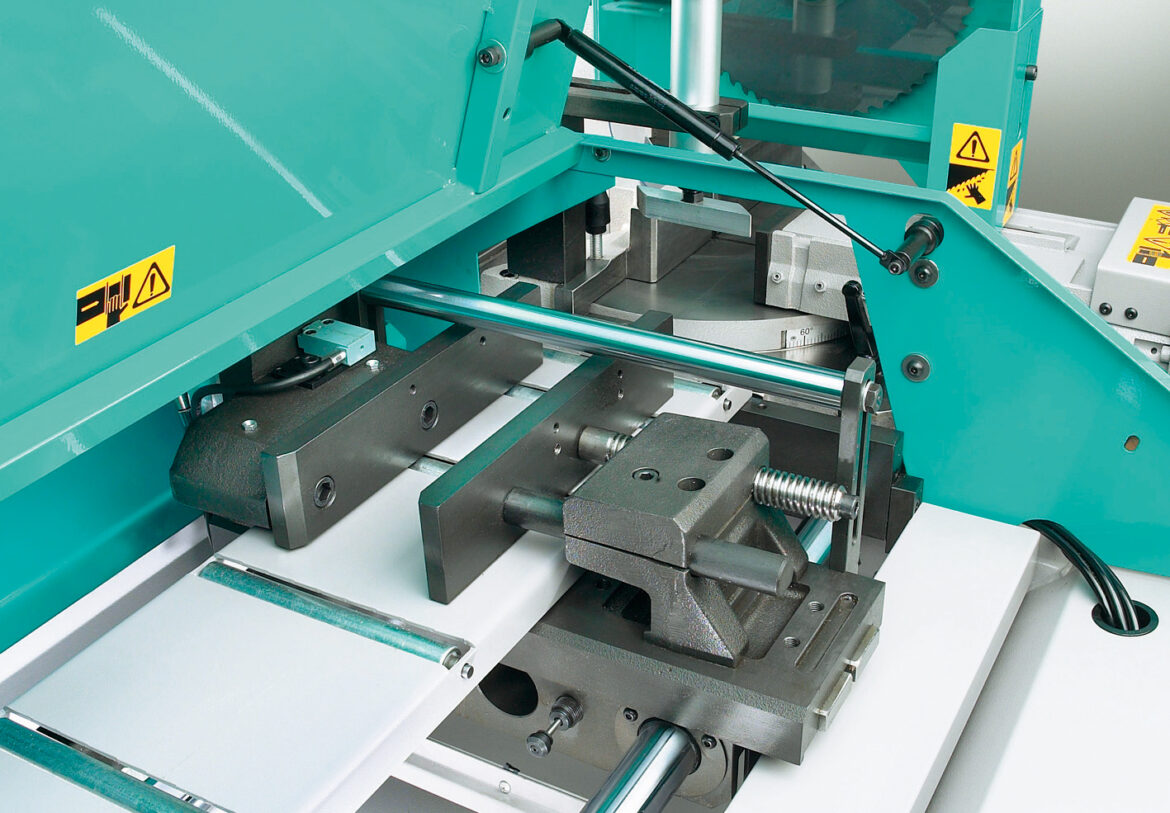

- Vice with adjustable guides, free to move alongside the worktable, with quick motion and clamping; anti-burr adjustable device, pneumatic vertical vice.

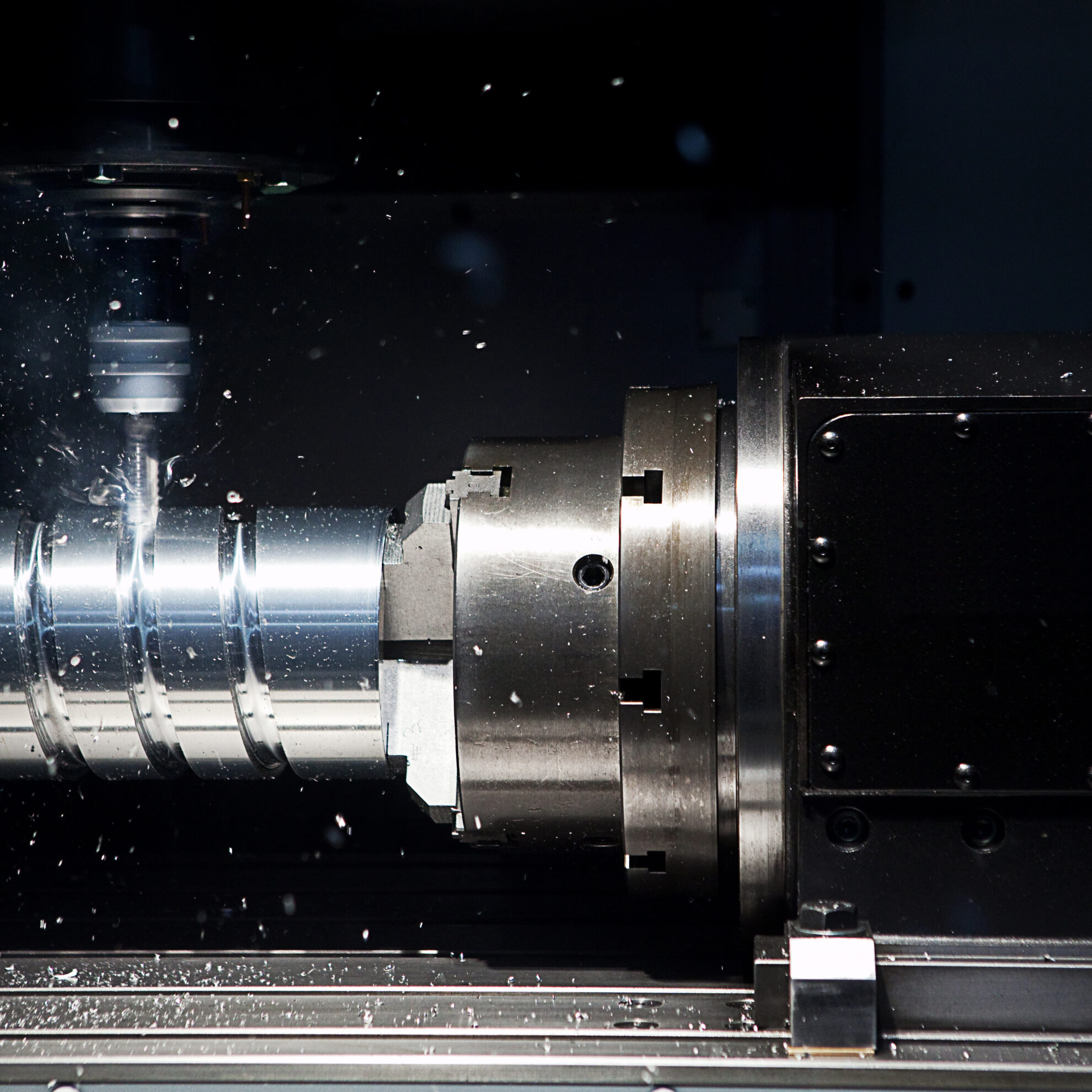

- Blade spindle with 40 mm diameter.

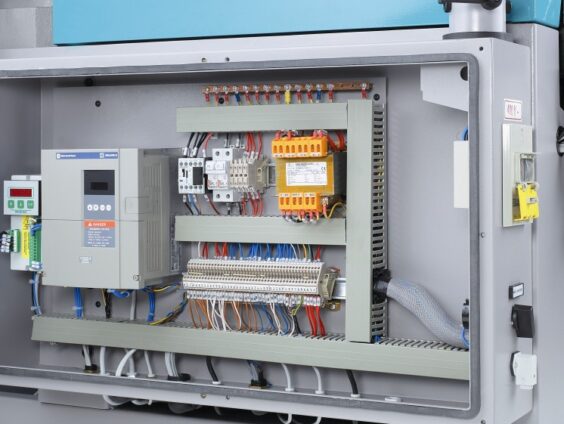

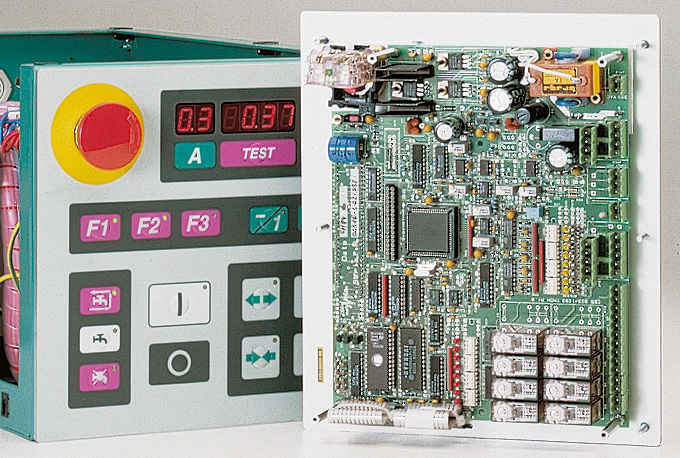

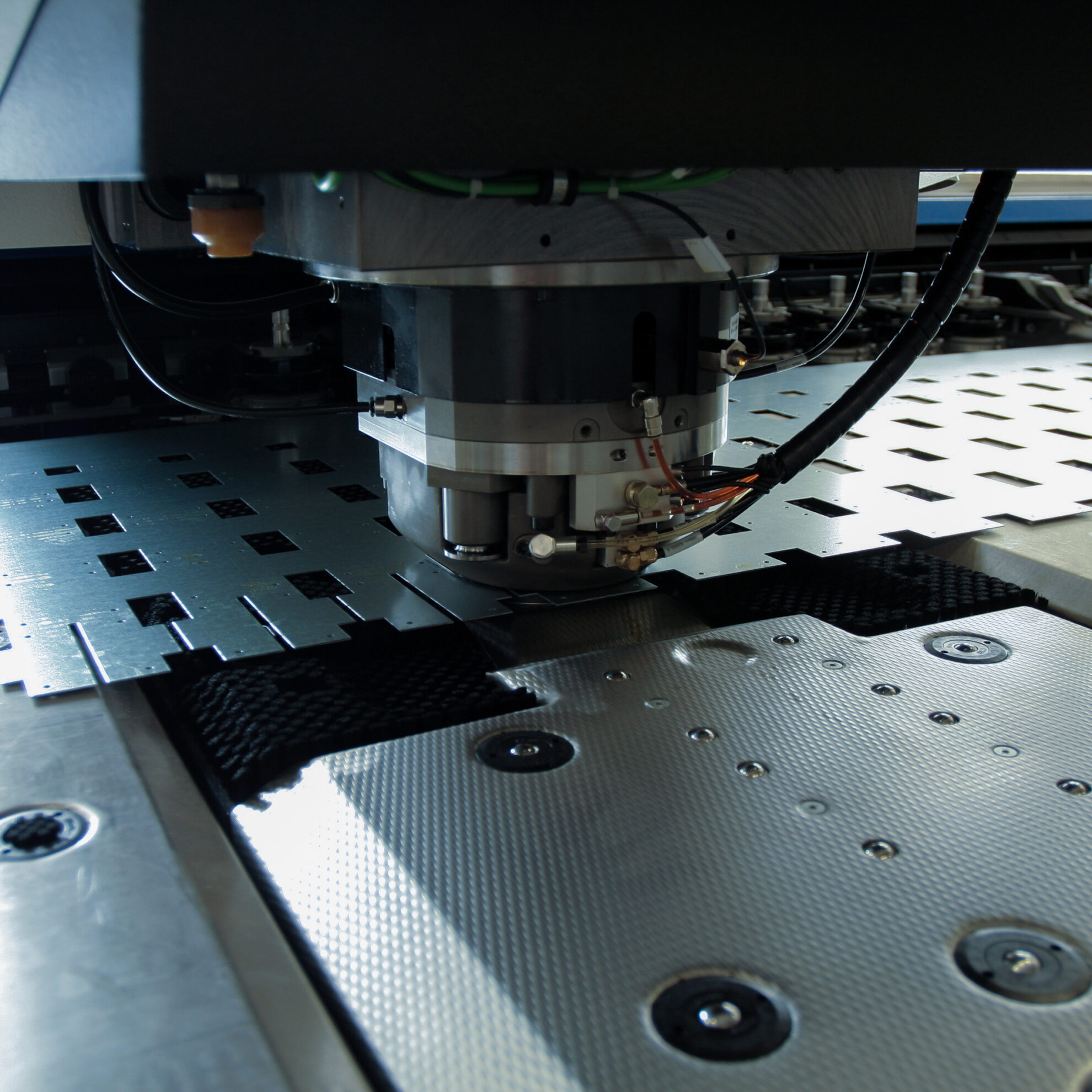

- Electronic driver with programming of all operations by means of the keyboard, including setting of the start-cut and end-cut points; machine status shown on display.

- Feeder with 200 mm opening, maximum stroke 520 mm,minimum stroke 4 mm (minimum scrap-end 170 mm); selection of the number of cuts (1-9999) and the feeder strokes (1- 29) by means of the keyboard.

- Cutting capacity at 90 °, round till 120 mm., square till 100 mm., rectangular till 180×100 mm.

| Sirio 370 AF-E | ||

| Area angular cut | ° | -45 / 90 / 30 |

| Cutting capacity at 90°: round / square / rectangular | mm. | 120 / 100 / 180 x 100 |

| Blade dimensions | mm. | 370 |

| Blade Motor Power | KW | 1.5 / 2.2 or 3 ESC |

| Run feeder carriage (repeatable) | mm. | 520 |

| Scrap end | mm. | 170 |

| Blade speed | RPM | 15/30 or 15 ÷ 70 ESC |

| Capacity coolant tank | Lt | 40 |

| Dimensions ( B x L x H ) | mm. | 1900 x 1450 x 2100 |

| Height of the work-table | mm. | 925 |

| Weight | Kg | 710 |

| Minimum cuttable length | mm. | 4 |

| Type of functioning | semiautomatic/automatic | |

| Suitable for cutting: | Steel / cast iron / high-strength steels | |