UNISIGN UNICOM6000 Vertical machining and turning center

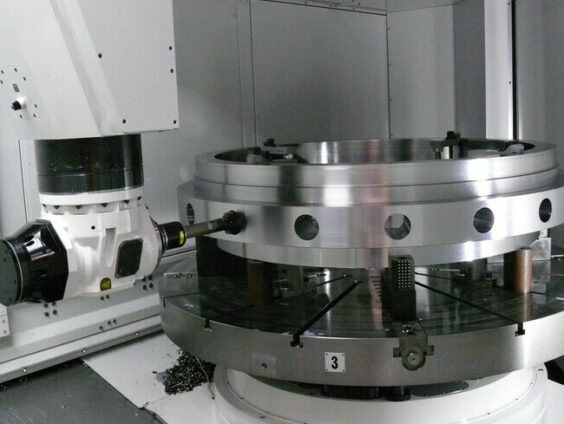

Automatic pallet changer for high uptime

Ideal for multi-tasking on complex components

Quality and productivity

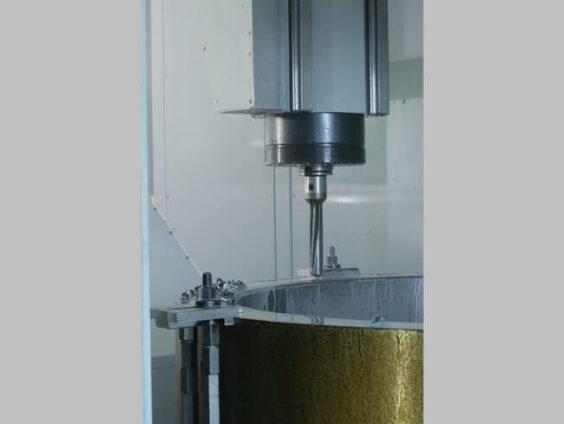

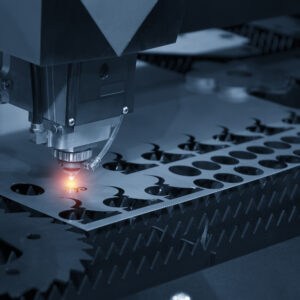

The UNICOM6000 is a multi-task machining centre that combines quality and productivity. It is capable of performing milling, drilling and vertical turning operations with ease. This workhorse machine has the distinct advantage of a ram design that allows ‘plunging’ inside the component with short turning tools. It can be equipped with several machining heads, which are stored in designated pick-up stations. For horizontal machining operations, an indexable right angular head is available and to create even further flexibility, a universal head with B- and C-axis can be integrated. The automatic pallet changer reduces loading times and ensures a high uptime to boost productivity. Even with its focus on output, this machine makes no compromise on accuracy.

Proven technology

Every multi-tasking machine aims to deliver productivity – but it must not be at the cost of product quality. The Unicom 6000 is one of a long line of vertical machining centres that have been developed by Unisign over the past 30 years. The proven technology built into the milling spindle, the (universal) angular head and the carousel turning table is your guarantee of reliability for years to come.

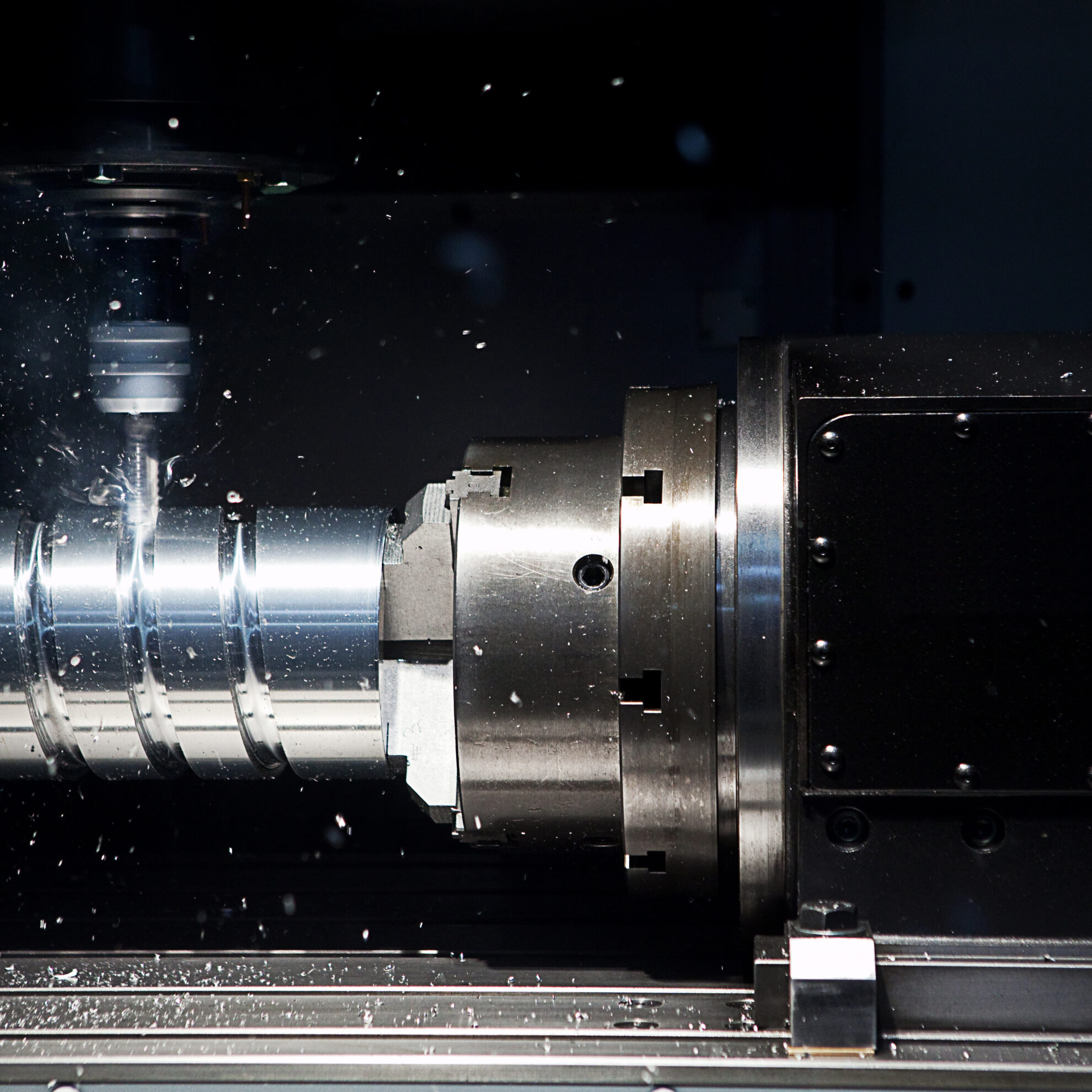

Powerful and smart

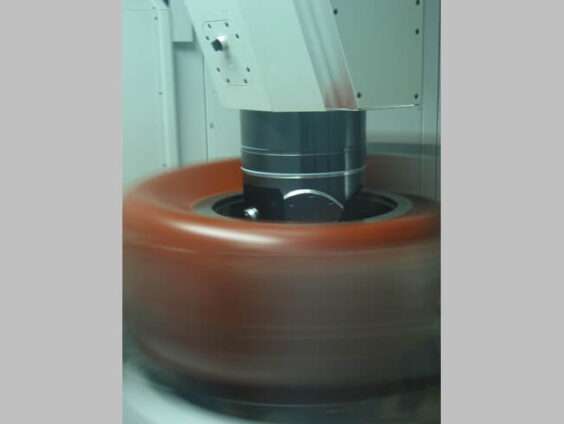

The carousel turning station has a double drive system with gearbox creating extreme power and torque for turning while also being able to run in C-axis mode. Together with the powerful main spindle, the UNICOM6000 offers extreme capacity in all aspects. The machine’s ram design allows ‘plunging’ into components for inside operations and the use of short tools.

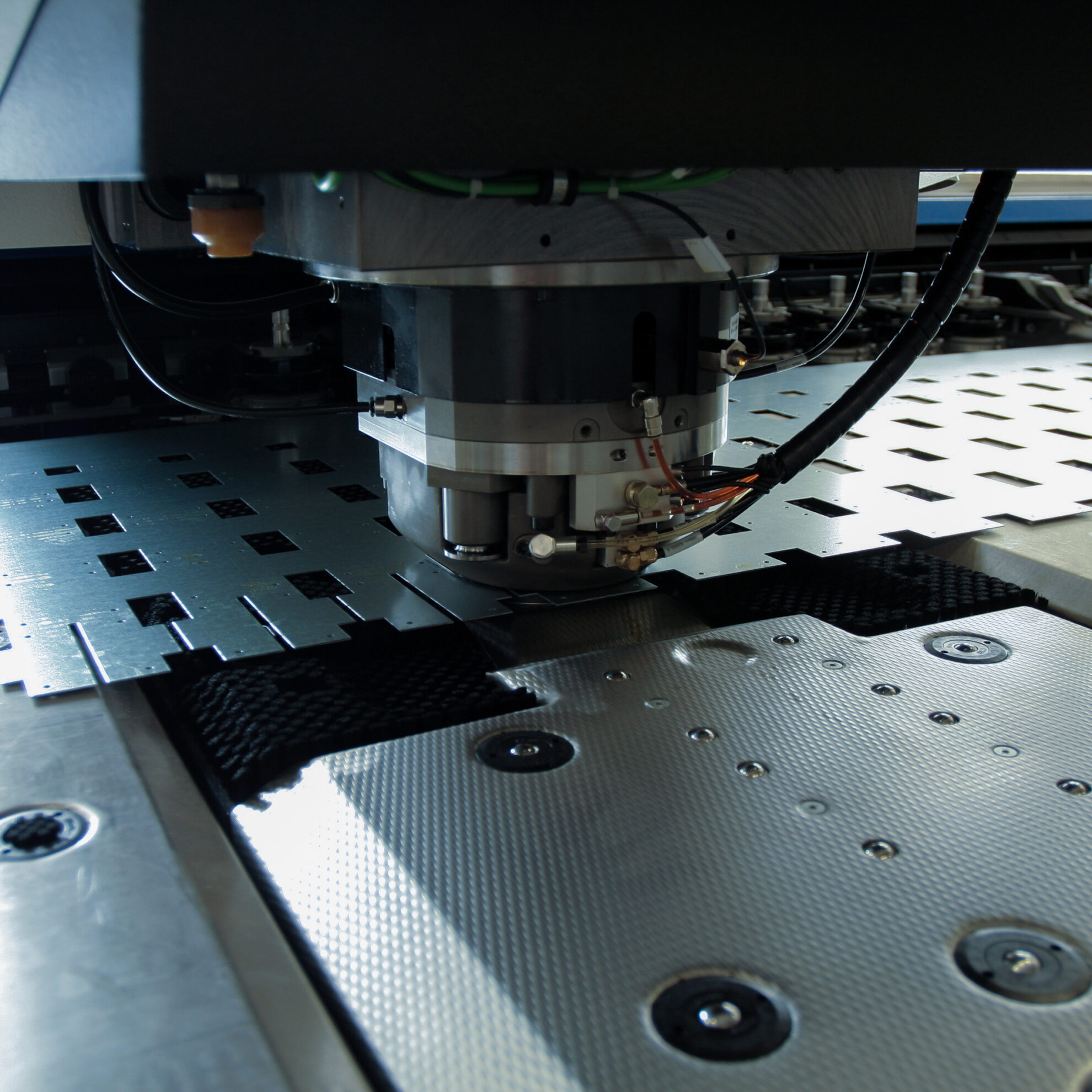

Operating comfort and safety

The UNICOM6000 is equipped with a fully enclosed guarding section and with fume extraction it creates an ergonomically safe and comfortable working environment. The ideal machine layout ensures an excellent view on all machining processes and gives easy access to the machining area and pallet changer. The UNICOM6000 comes standard with 2 pallets but more are optional. The pallets come in various sizes and can be used randomly. The components can be precisely aligned and centred on the pallet loading station, thus eliminating time-consuming measuring inside the machine. Pallets can be changed within 60 seconds.

Pallet changer standard

Right angular indexing head

Universal indexing head

Various turning tool adaptors

In-process measuring

| Work area | |

| X-axis | 1.950mm |

| Y-axis | 1.425 mm |

| Z-axis | 1.000/1.250 mm |

| Vertical clearnance | 1.300/1.550 mm |

| Table | |

| Table size | 1.250 – 1.800 ø mm |

| Swing circle | 2.000 ø mm |

| Spindle | |

| Gear box driven spindle and values | 54 kW |

| 6.000 min-1 | |

| 1.000 Nm | |

| Carousel turning station | 70 / 95 kW |

| 25.000 / 38.000 Nm | |

| Various | |

| Tooling | HSK100A / Capto C8 |

| Taper size | |

| Number of pockets | # 80-202 |

| Tool change time | 10 sec |

| Speed | |

| Rapid traverse | 30.000 mm/min |

| Feed Rate | 5-30.000 mm/min |