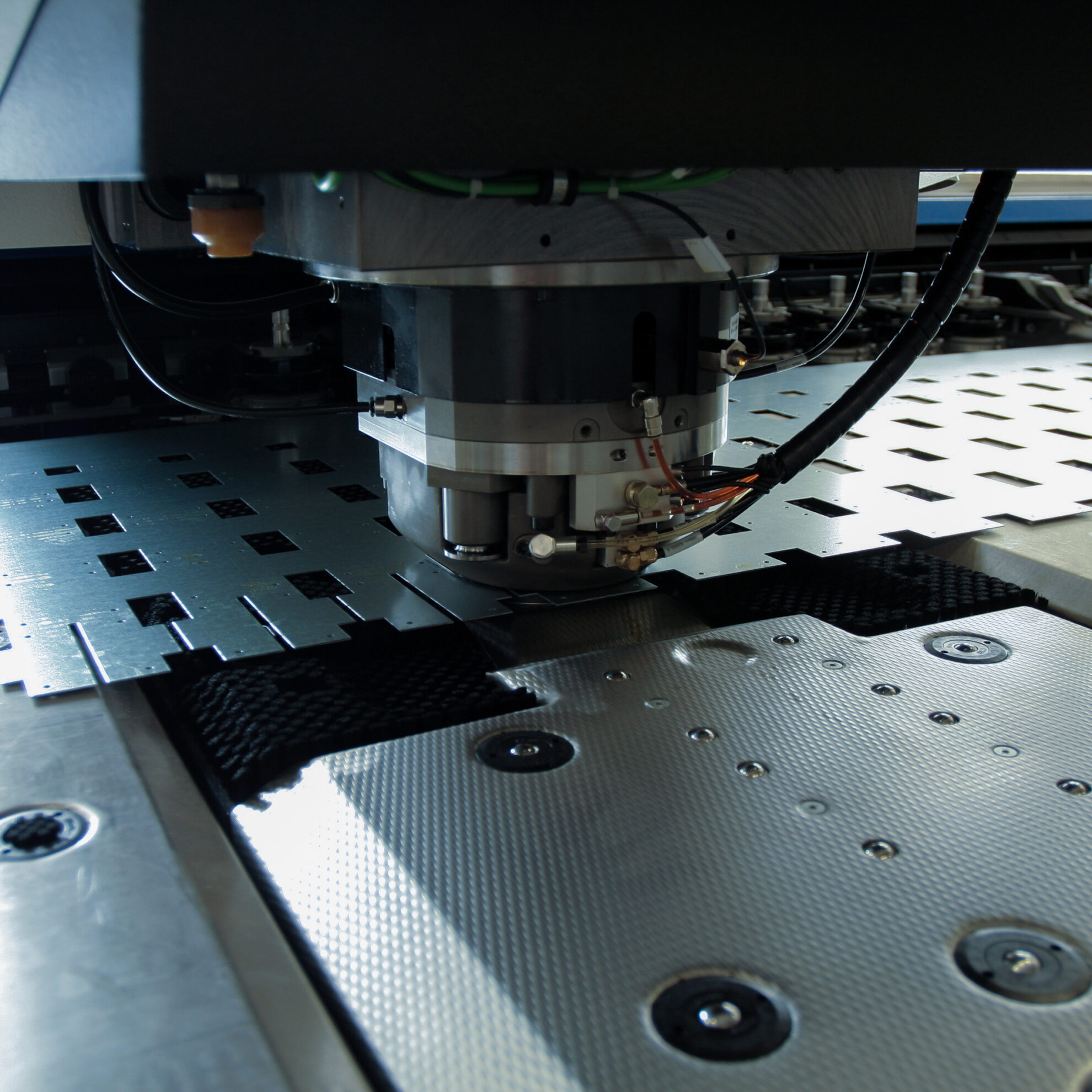

UNISIGN UNIPORT 6000 – HV Five Axis Portal CNC Machining Centre

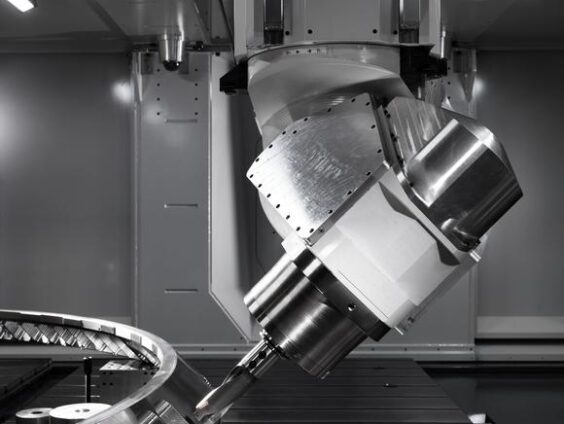

True flexibility The HV (horizontal/vertical) variant of the Uniport 6000 is a truly cost-effective choice for 5-axis machining of large components. In addition to its generous daylight opening, the Uniport 6000-HV features a tilting nutator head. This can travel through an angle of 100°, going from a vertical plane to 10° over the horizontal, making it possible to adopt even the most extreme machining angles. Coupled with outstanding price/performance, this compact portal machine is a must if you’re looking for true flexbility.

Affordable perfomance

The Uniport 6000-HV with its 2-axis nutator head has a host of productivity features that make it a truly flexible machining centre. What sets it apart is the large horizontal and vertical opening, which makes it possible to machine extremely big parts on a compact portal machine. And that translates into an amazing price/performance ratio from an affordable solution.

Any angle

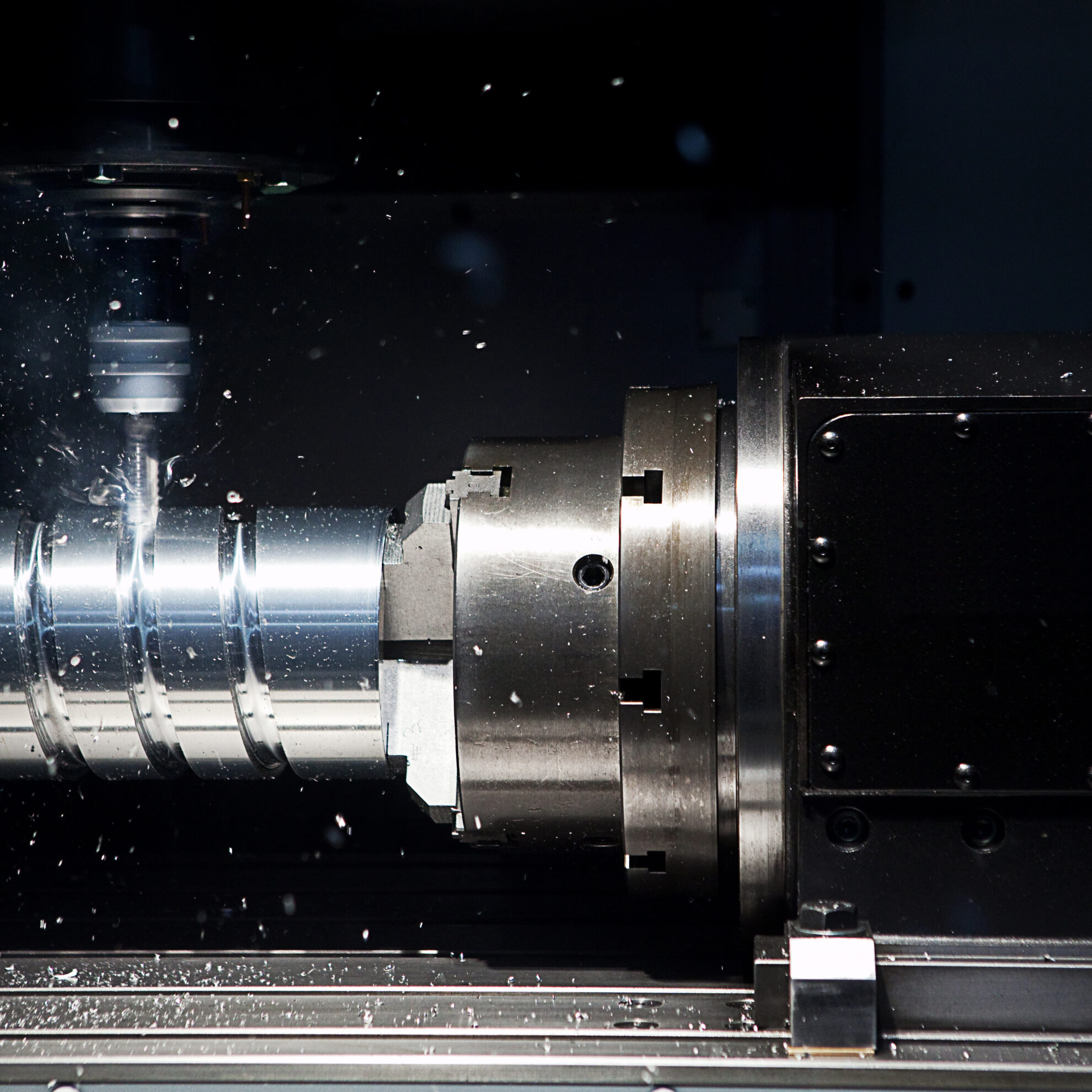

Able to machine any angle or plane without restriction, this machine with its 2-axis head and cross slide construction is a well thought-out concept that has been developed using proven technology. The drive for the continuously variable B-axis and C-axis is cooled to enhance thermal performance, maintaining accurate positioning. The high speed motor spindle and rapid traverse (40.000 mm/min) give it outstanding dynamic properties.

Full view

The Uniport 6000-HV incorporates a travelling platform with an operator cabin fixed to the right hand column. This makes it easy for operators to ride along safely and keep the machining process in full view. When the time comes to change workpieces, the low step makes getting on to the table extremely easy. The work area is flexible too, with the option to use the entire space for one large piece, or to adopt pendulum machining with the two stations separated by a screen.

Operator platform

Pendulum mode

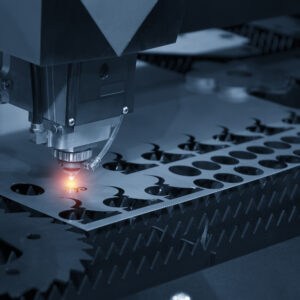

Tool measuring and tool break via laser

Siemens / Heidenhain

| Work area | |

| X-axis | 4.000 – 20.000+ mm |

| Y-axis | 2.500 – 6.000 mm |

| Z-axis | 1.500 / 1.800 mm |

| Vertical clearance | 1.700 / 2.000 mm |

| Distance spindle nose to table vertical position | 200 – 2.000 mm |

| Distance spindle nose to table horizontal position | 190 – 1.950 mm |

| Width between columns | 1.500 – 4.000 mm |

| Spindle | |

| Nutator head with motor spindle | 63/82 kW |

| 8.000/15.000 min-1 | |

| 550/391 Nm | |

| B-axis | ±110 |

| C-axis | ±185 |

| Various | |

| Tooling | |

| Taper size | HSK100A |

| Number of pockets | # 38-159 |

| Tool change time | 12 sec |

| Speed | |

| Rapid traverse | 40.000 mm/min |

| Feed Rate | 5-40.000 mm/min |

| Speed B- and C-axis | 15.000 min-1 |