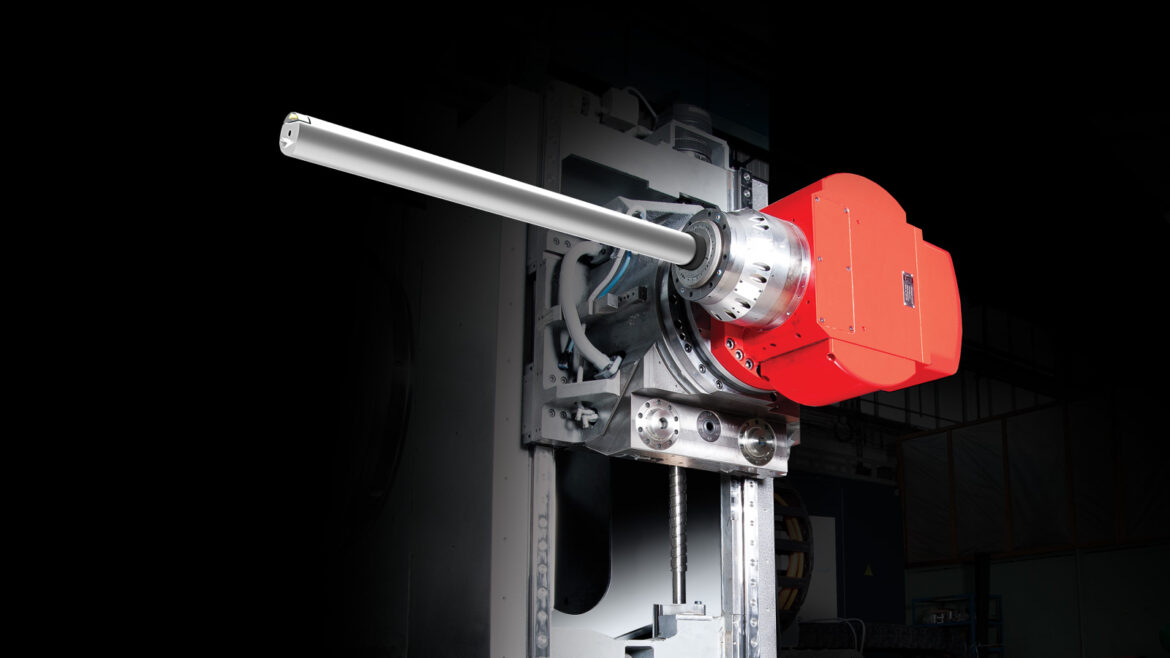

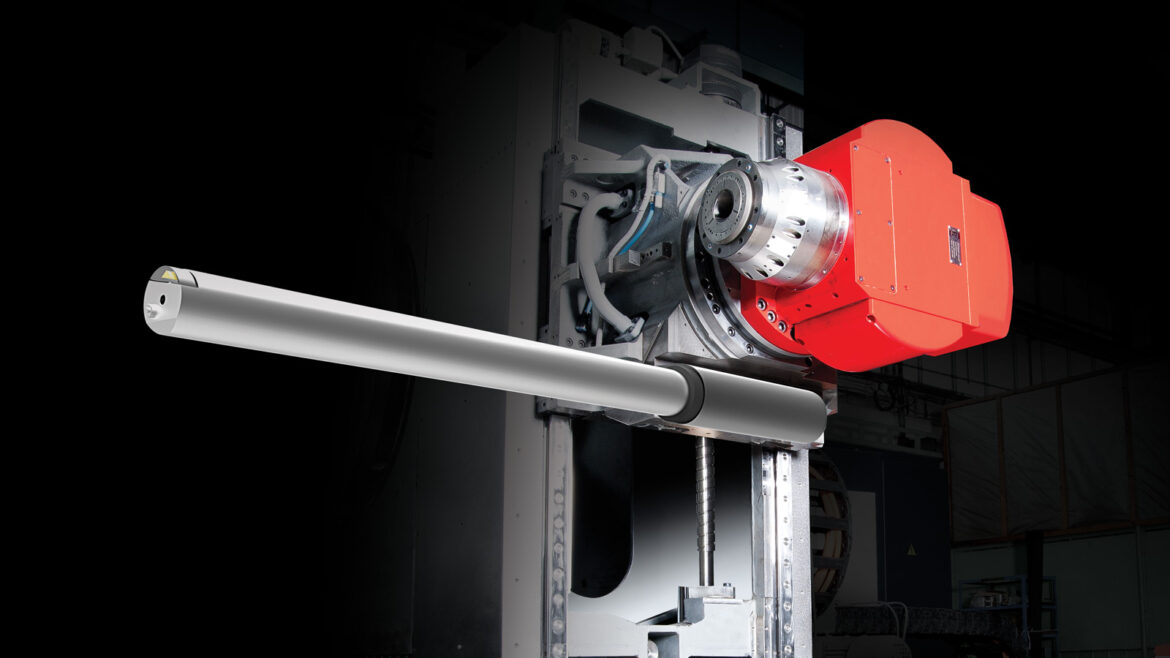

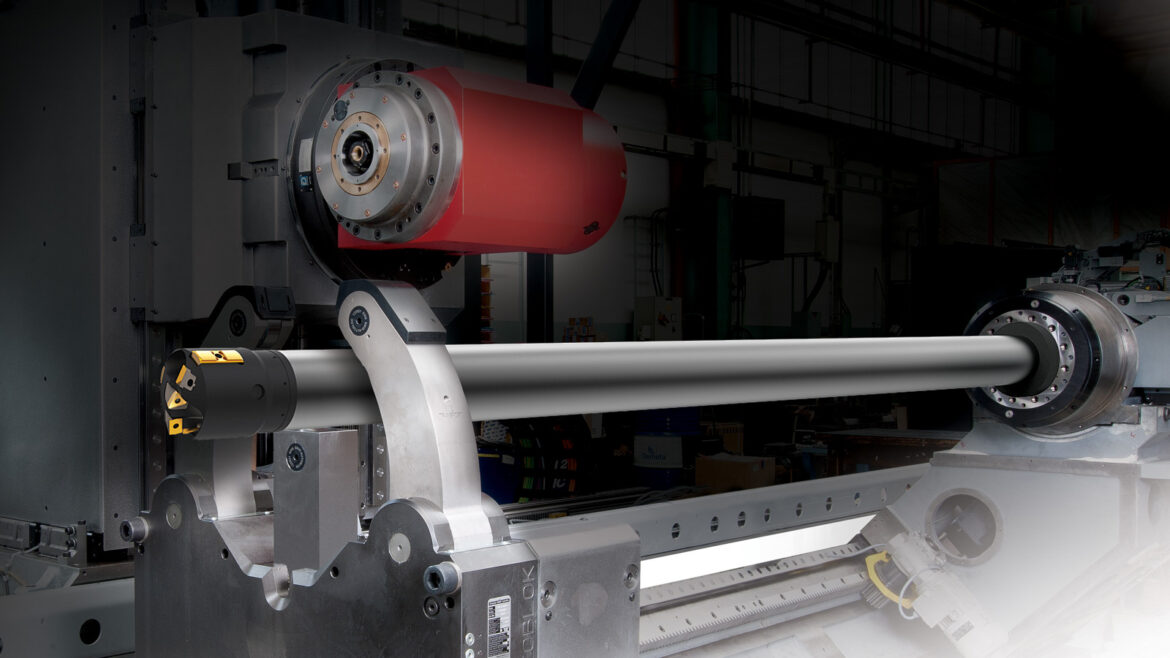

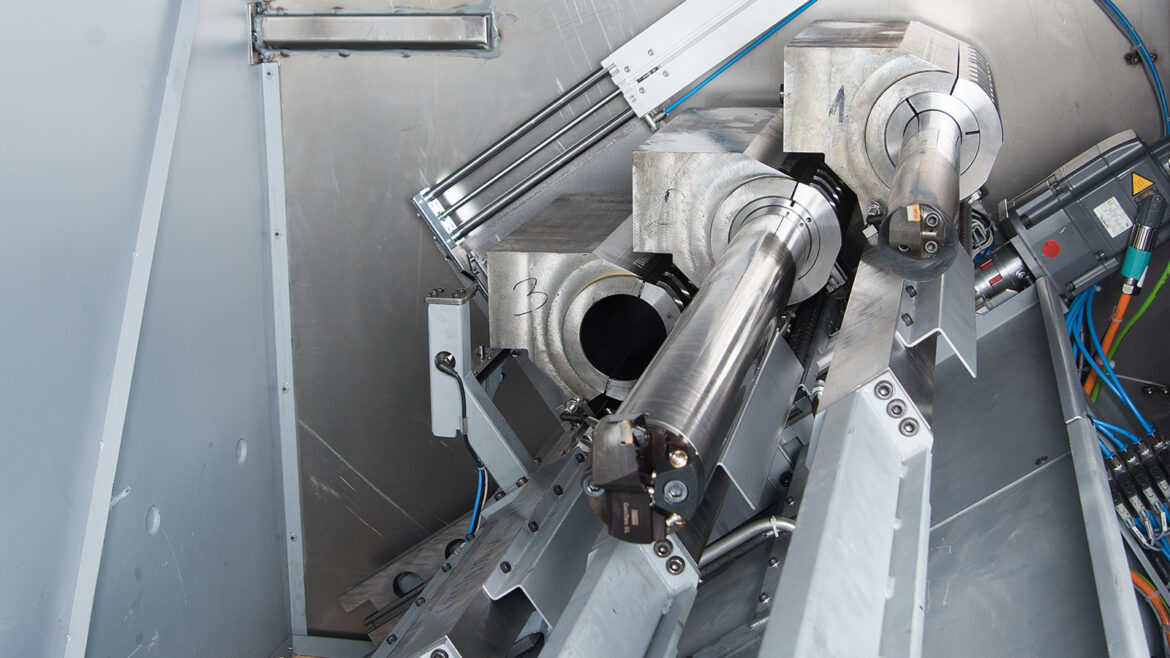

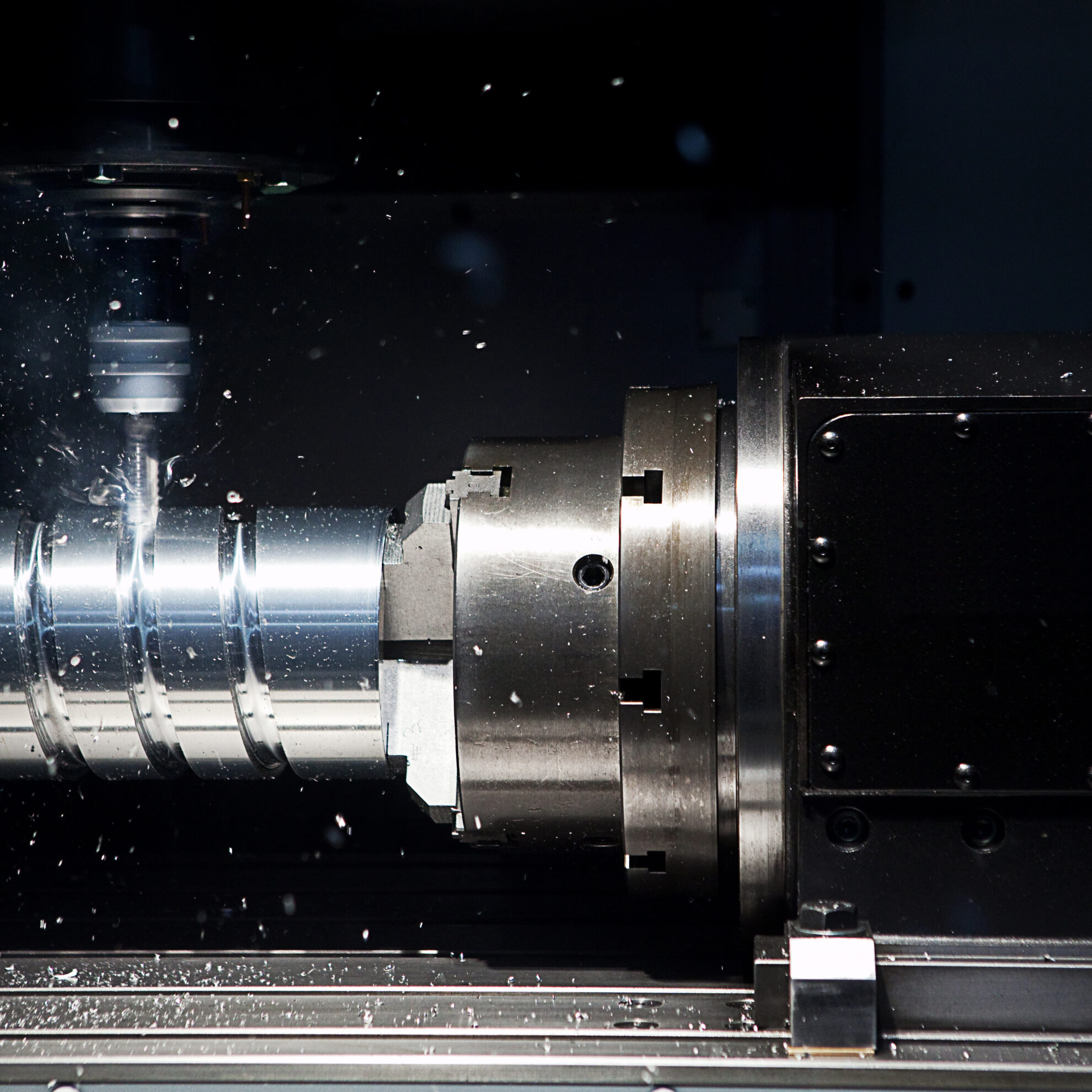

KOVOSVIT MULTICUT 630 Multi-tasking turning milling machining center

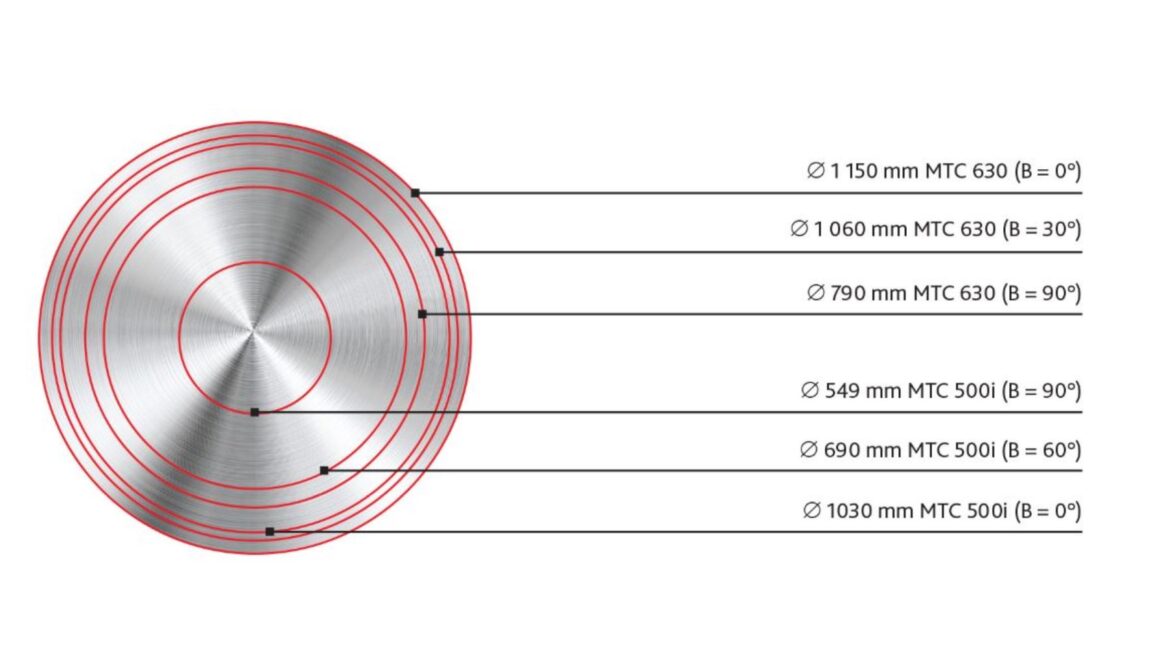

Max. turning dia: 1 150 mm

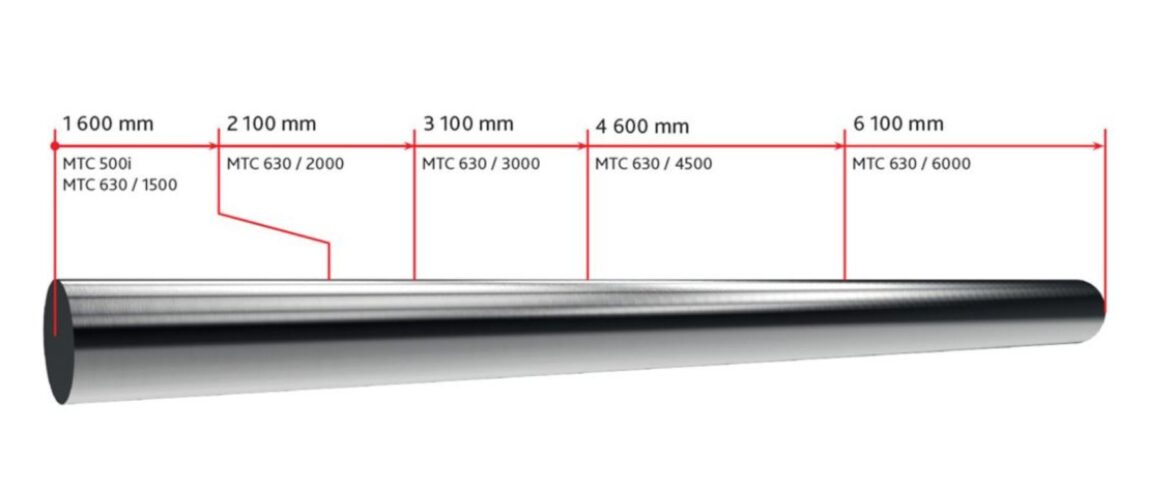

Max. turning length: 1 600 / 2 100 / 3 100 / 4 500 / 6 100 mm

Max. Workpiece weight: 4 000 Kg

Max.output S1 / S6 – 40%: 41 / 62 kW

Mill turn center

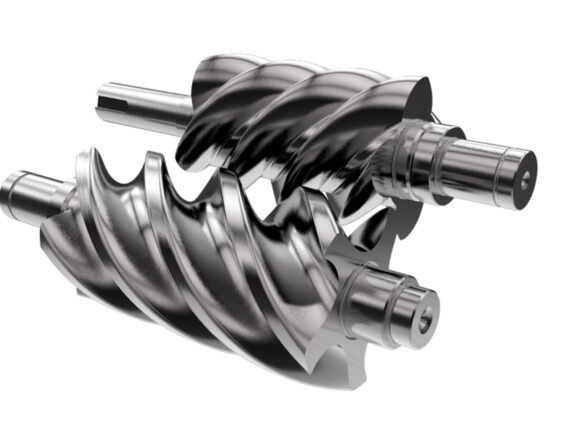

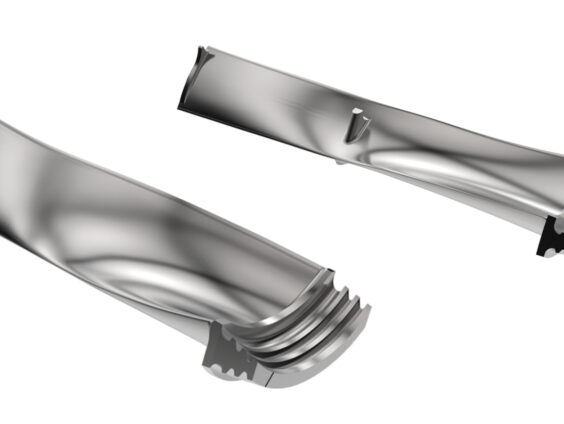

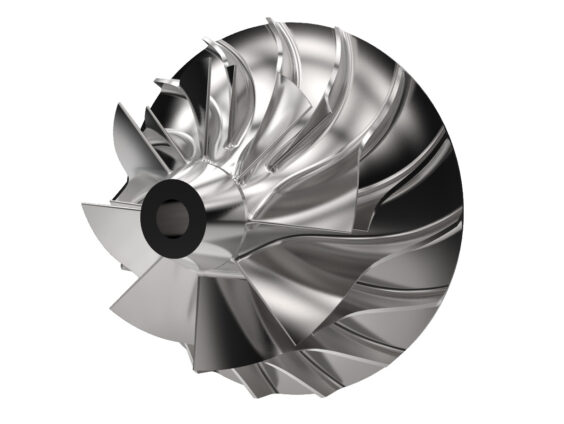

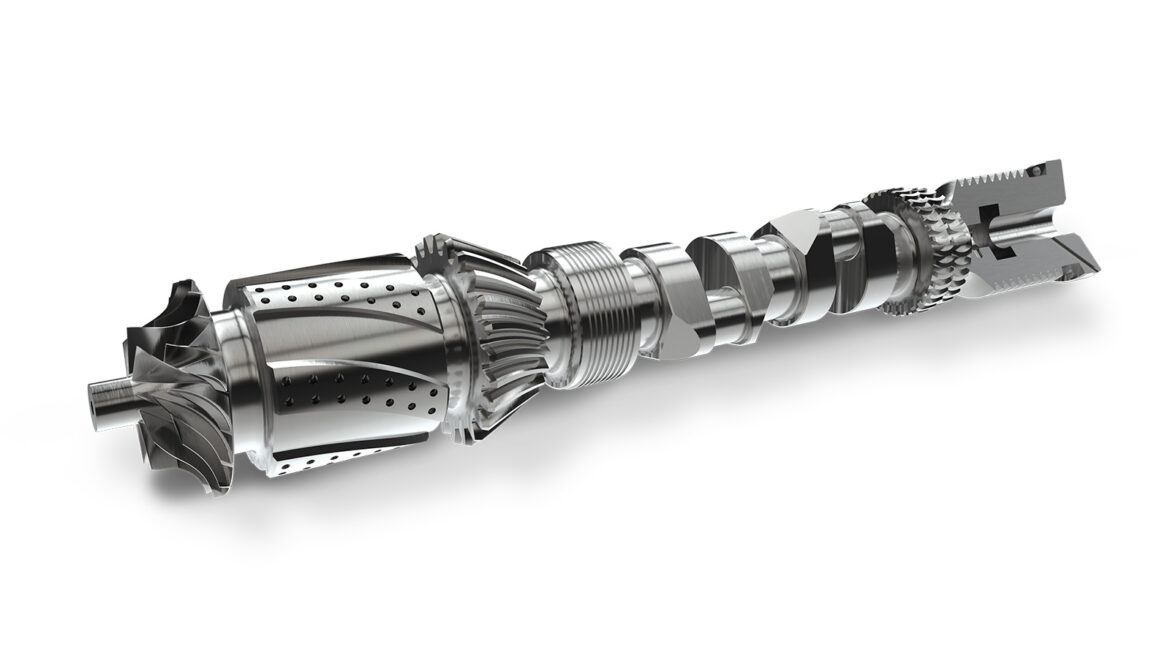

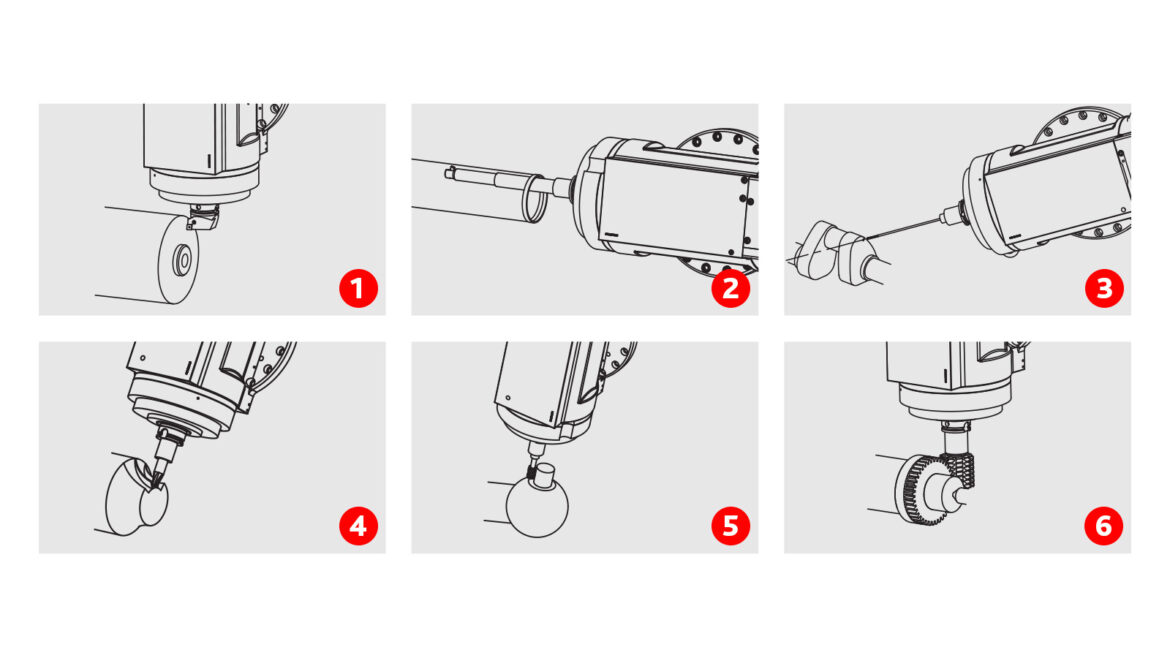

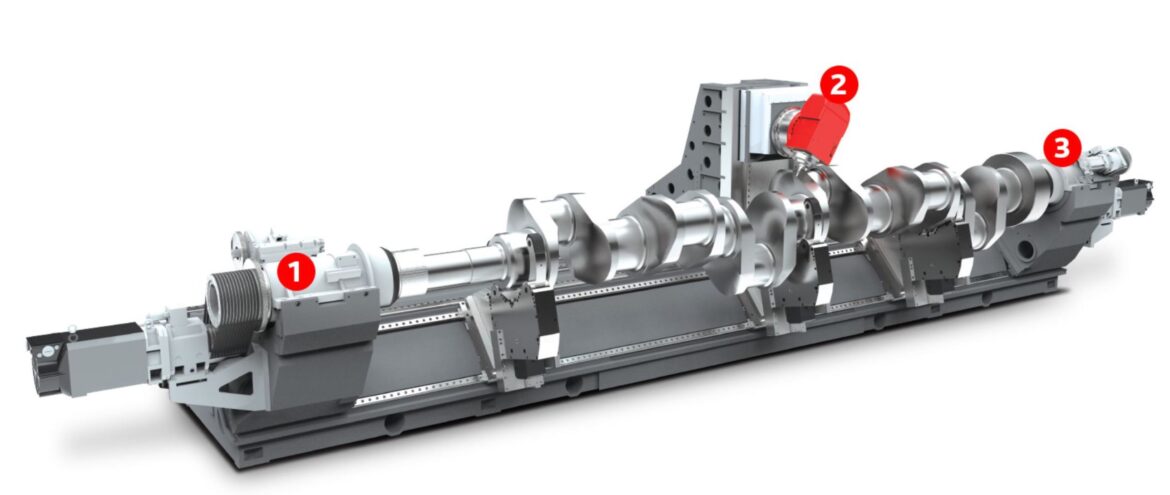

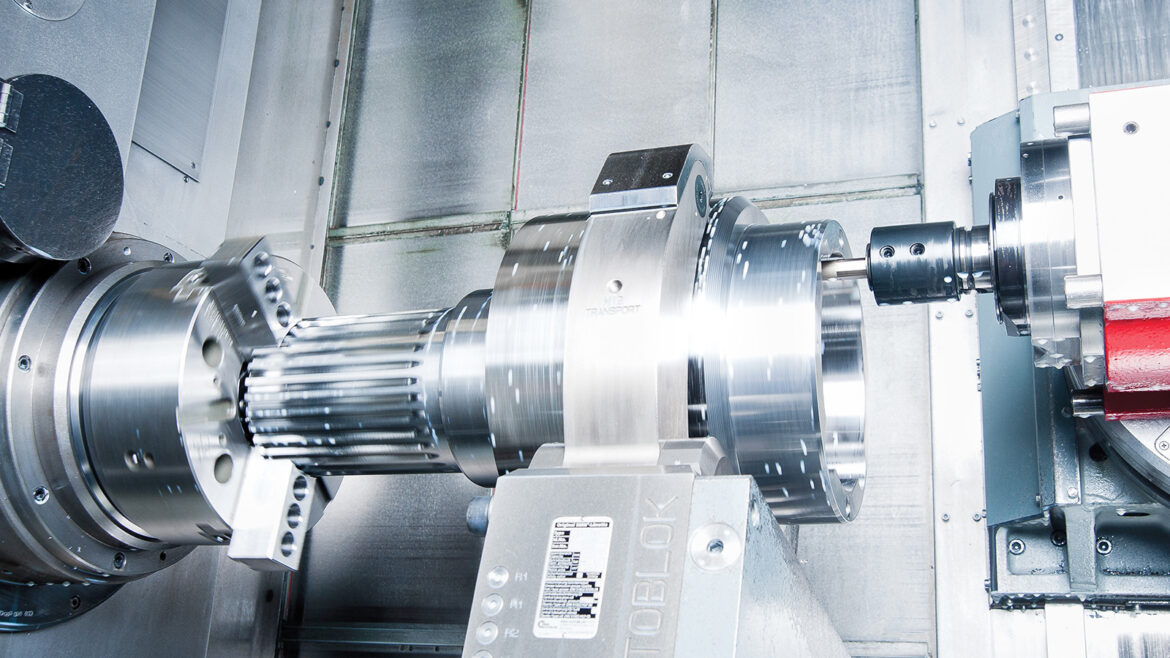

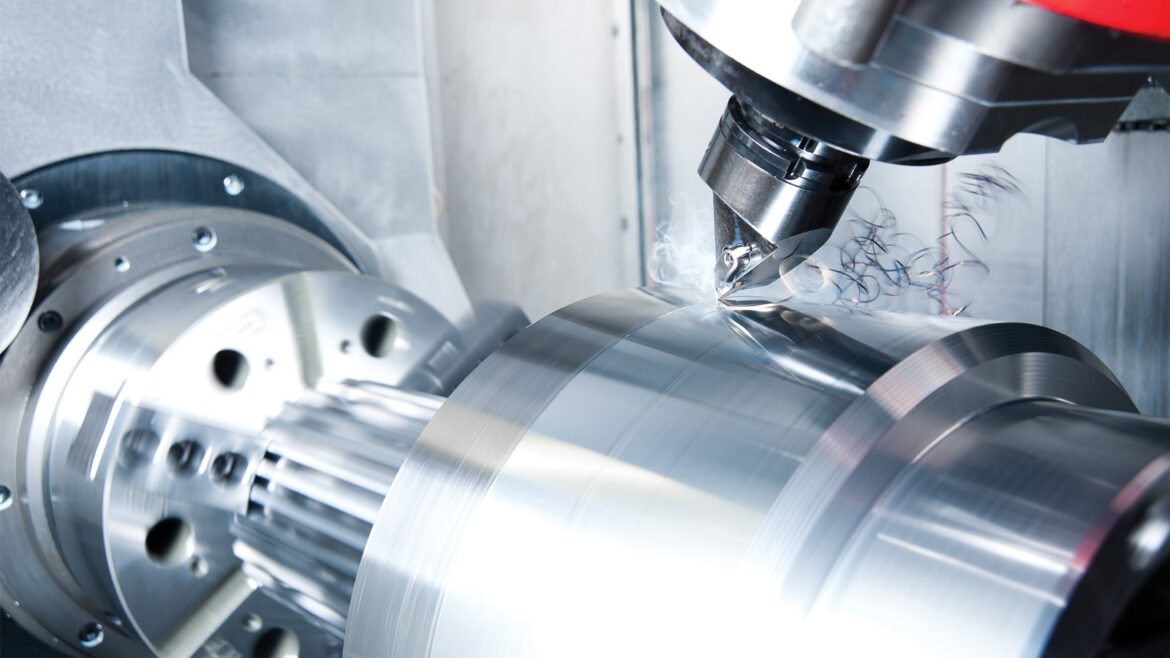

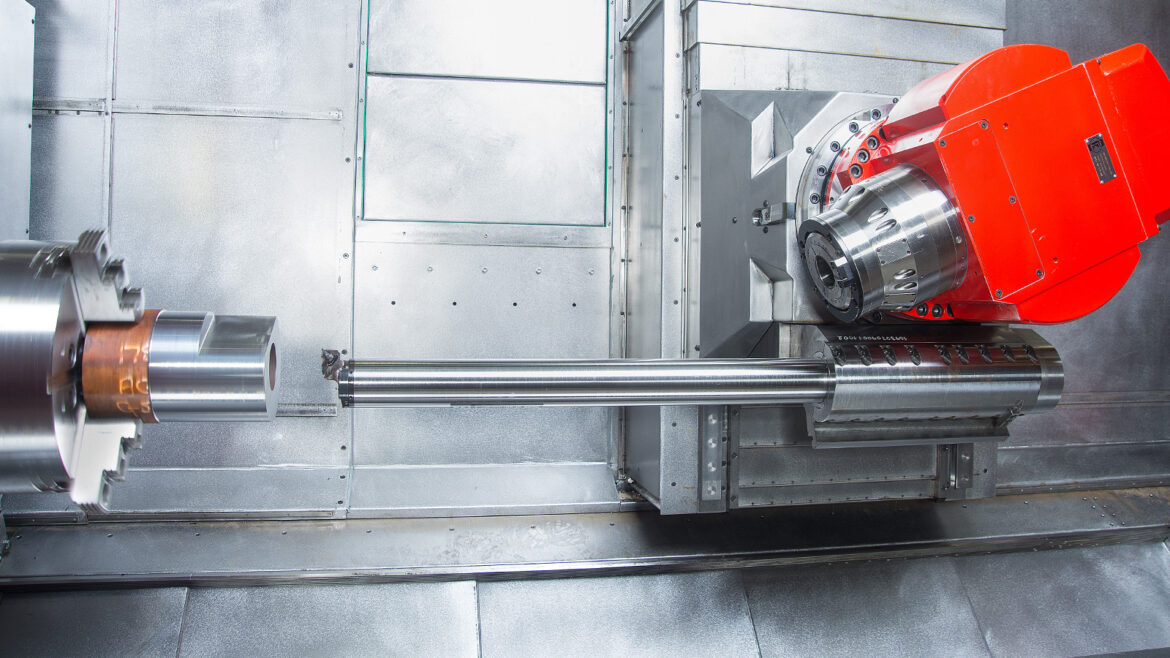

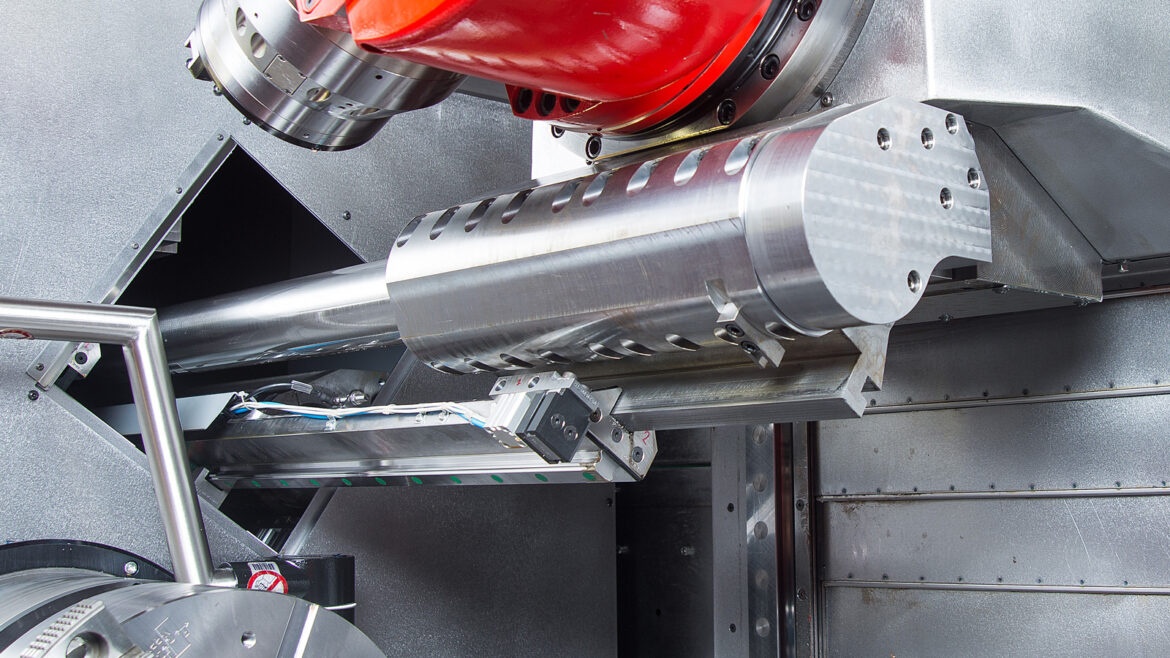

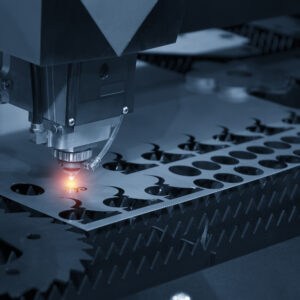

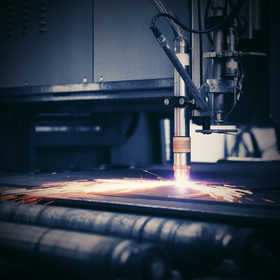

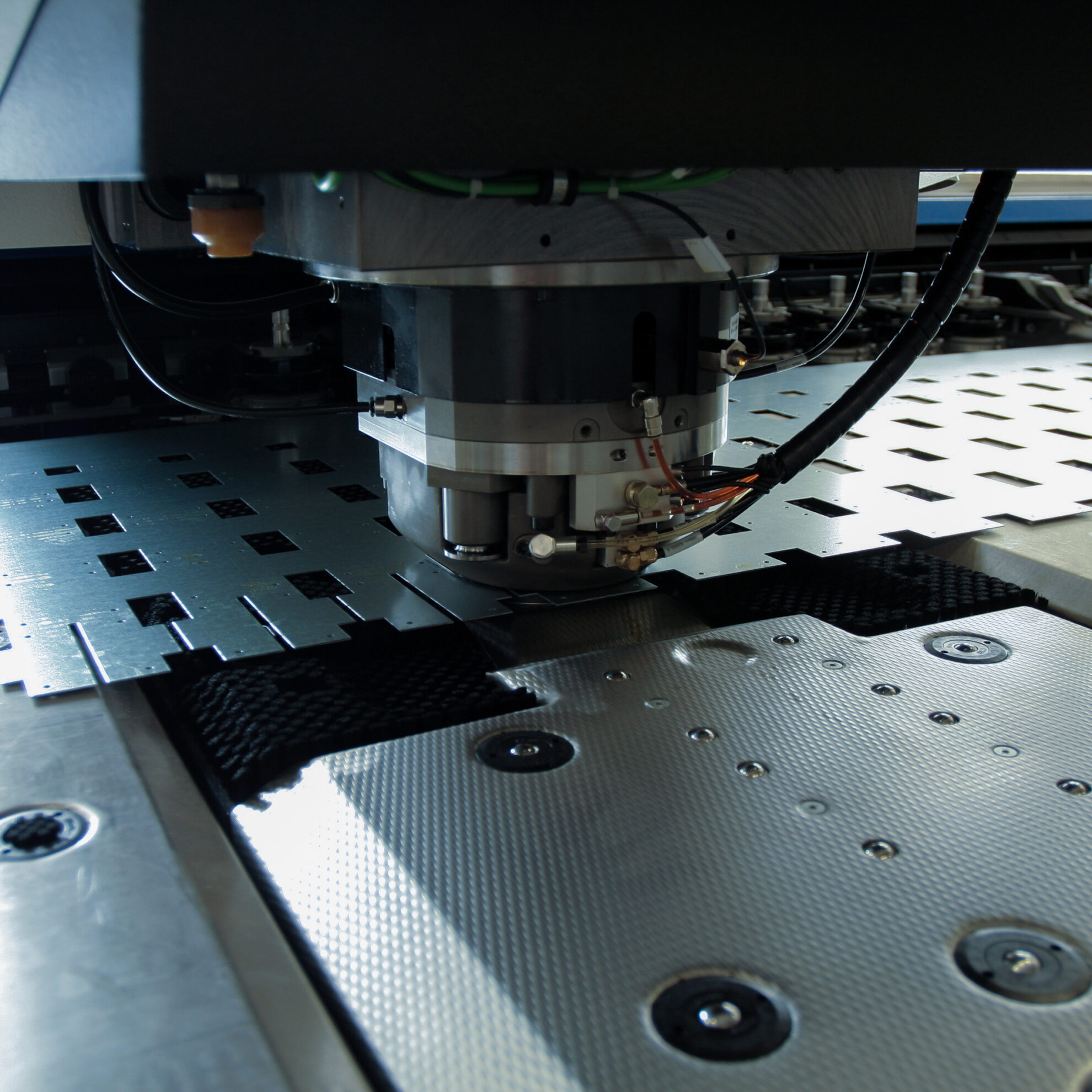

The multitasking mill turn center combine the features of turning and milling machines in a single universal machine which has capability to machine complex parts using more technologies (turning, threading, recessing, drilling, boring, milling, cam milling, gear hobbing, grinding and measuring). The machines are equipped with a B-axis as standard which allows an extra-axial drilling and 5-axis milling. The MULTICUT 630 (with the right spindle) can do a full part machining on both sides.

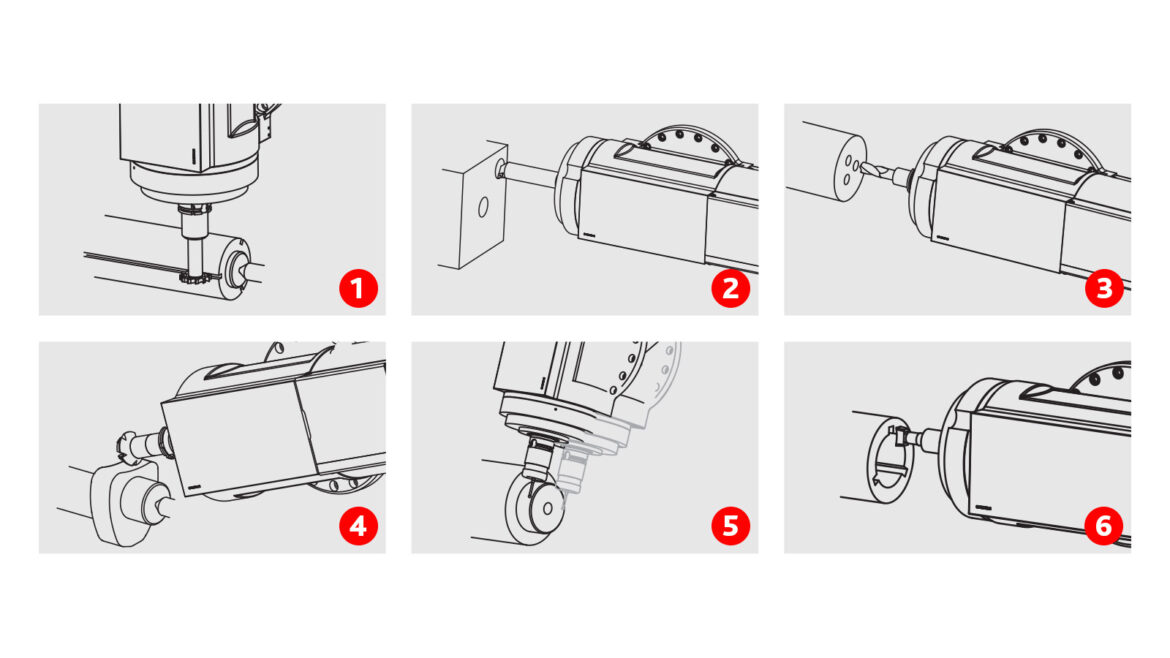

Machine version:

S – version with the subspindle

T – version with the tailstock

| TECHNICAL DATA | MULTICUT 630 / 1500 (T) | MULTICUT 630 / 1500 (S) | MULTICUT 630 / 2000 (T) | MULTICUT 630 / 2000 (S) | MULTICUT 630 / 3000 (T) | MULTICUT 630 / 3000 (S) | MULTICUT 630 / 4500 (T) | MULTICUT 630 / 4500 (S) | MULTICUT 630 / 6000 (T) | MULTICUT 630 / 6000 (S) | |

| Operating range | |||||||||||

| Max. turning diameter B=0° / 45° / 60° / 90° | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | 790 / 930 / 1060 / 1150 | |

| Max. turning lenght | mm | 1600 | 1600 | 2100 | 2100 | 3100 | 3100 | 4600 | 4600 | 6100 | 6100 |

| Bar work capacity | mm | 122 | 122 | 12 | 122 | 122 | 122 | 122 | 122 | 122 | 122 |

| Workpiece weight | |||||||||||

| Not supported / supported with center (max. speed) with a chuck | kg | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) | 1000 / 2500 (250min-1) |

| Supported with steady rests 1 / 2 / 3 (max. speed) with a chuck | kg | 3000 / – / – (250min-1) | 3000 / – / – (250min-1) | 3000 / 3500 / – (250min-1) | 3000 / 3500 / – (250min-1) | 3000 / 3500 / – (250min-1) | 3000 / 3500 / – (250min-1) | 3000 / 3500 / 4000 (250min-1) | 3000 / 3500 / 4000 (250min-1) | 3000 / 3500 / 4000 (250min-1) | 3000 / 3500 / 4000 (250min-1) |

| Linear axes of the tool spindle | |||||||||||

| X / Y <-Y/+Y> / Z axis travel | mm | 780 / 400 <+-200> / 1600 | 780 / 400 <+-200> / 1600 | 780 / 400 <+-200> / 2100 | 780 / 400 <+-200> / 2100 | 780 / 400 <+-200> / 3100 | 780 / 400 <+-200> / 3100 | 780 / 400 <+-200> / 4600 | 780 / 400 <+-200> / 4600 | 780 / 400 <+-200> / 6100 | 780 / 400 <+-200> / 6100 |

| X / Y / Z axis rapid traverse | m.min-1 | 40 / 30 / 40 | 40 / 30 / 40 | 40 / 30 / 40 | 40 / 30 / 40 | 40 / 30 / 40 | 40 / 30 / 40 | 40 / 30 / 40 | 40 / 30 / 40 | 40 / 30 / 40 | 40 / 30 / 40 |

| Main spindle | |||||||||||

| Max. spindle speed | |||||||||||

| Low speed | min-1 | 720 | 720 | 720 | 720 | 720 | 720 | 720 | 720 | 720 | 720 |

| High speed | min-1 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 |

| Gearbox stages | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Spindle nose type (DIN 55026) | A11 | A11 | A11 | A11 | A11 | A11 | A11 | A11 | A11 | A11 | |

| Torque | |||||||||||

| Low speed 25% / 40% / 60%ED / continuous | Nm | – / – / 3283 / 2736 | – / – / 3283 / 2736 | – / – / 3283 / 2736 | – / – / 3283 / 2736 | – / – / 3283 / 2736 | – / – / 3283 / 2736 | – / – / 3283 / 2736 | – / – / 3283 / 2736 | – / – / 3283 / 2736 | – / – / 3283 / 2736 |

| High speed 25% / 40% / 60%ED / continuous | Nm | 1040 / 821 / 657 / 547 | 1040 / 821 / 657 / 547 | 1040 / 821 / 657 / 547 | 1040 / 821/ 657 / 547 | 930 / 821 / 657 / 547 | 930 / 821 / 657 / 547 | 930 / 821 / 657 / 547 | 930 / 821 / 657 / 547 | 930 / 821 / 657 / 547 | 930 / 821 / 657 / 547 |

| Motor power 25% / 40% / 60%ED / continuous | kW | 78 / 61,5 / 49 / 41 | 78 / 61,5 / 49 / 41 | 78 / 61,5 / 49 / 41 | 78 /61,5 /49 /41 | 70 / 61,5 / 49 / 41 | 70 / 61,5 / 49 / 41 | 70 / 61,5 / 49 / 41 | 70 / 61,5 / 49 / 41 | 70 / 61,5 / 49 / 41 | 70 / 61,5 / 49 / 41 |

| Subspindle | |||||||||||

| Max. spindle speed | |||||||||||

| Low speed | min-1 | – | 720 | – | 720 | – | 720 | – | 720 | – | 720 |

| High speed | min-1 | – | 2800 | – | 2800 | – | 2800 | – | 2800 | – | 2800 |

| Gearbox stages | – | 2 | – | 2 | – | 2 | – | 2 | – | 2 | |

| Spindle nose type (DIN 55026) | – | A11 | – | A11 | – | A11 | – | A11 | – | A11 | |

| Torque | – | – | – | ||||||||

| Low speed 25% / 40% / 60%ED / continuous | Nm | – | – / – / 3110 / 2592 | – | – / – / 3110 / 2592 | – | – / – / 3110 / 2592 | – | – / – / 3110 / 2592 | – | – / – / 3110 / 2592 |

| High speed 25% / 40% / 60%ED / continuous | Nm | – | 881 / 762 / 622 / 518 | – | 881 / 762 / 622 / 518 | – | 881 / 762 / 622 / 518 | – | 881 / 762 / 622 / 518 | – | 881 / 762 / 622 / 518 |

| Motor power 25% / 40% / 60%ED / continuous | kW | – | 73 / 63 / 51,5 / 43 | 7- | 73 / 63 / 51,5 / 43 | – | 73 / 63 / 51,5 / 43 | – | 73 / 63 / 51,5 / 43 | – | 73 / 63 / 51,5 / 43 |

| C-axis of workpiece spindles | |||||||||||

| Min. programming step | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | |

| Max. speed | min-1 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Torque 25% ED / continuous | Nm | 2176 / 1408 | 2176 / 1408 | 2176 / 1408 | 2176 / 1408 | 2176 / 1408 | 2176 / 1408 | 2176 / 1408 | 2176 / 1408 | 2176 / 1408 | 2176 / 1408 |

| Brake | Nm | 3000 / 1000 | 3000 / 1000 | 3000 / 1000 | 3000 / 1000 | 3000 / 1000 | 3000 / 1000 | 3000 / 1000 | 3000 / 1000 | 3000 / 1000 | 3000 / 1000 |

| Tool spindle | |||||||||||

| Max. speed | min-1 | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] | 12 000 [10 000; 6500] |

| Taper | kVa | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] | HSK-A63 [HSK-A100 / Capto C6 / Capto C8] |

| Torque 25% / 40% ED / continuous | Nm | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] | 162 / 143 / 119 [216 / 180 / 140; 300 / 255 / 200] |

| Power 25% / 40% ED / continuous | kW | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] | 34 / 30 / 25 [56 / 47 / 37; 44 / 38 / 29] |

| Number of tool indexing positions | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | continuous [8 x 45°; 8 x 45°] | |

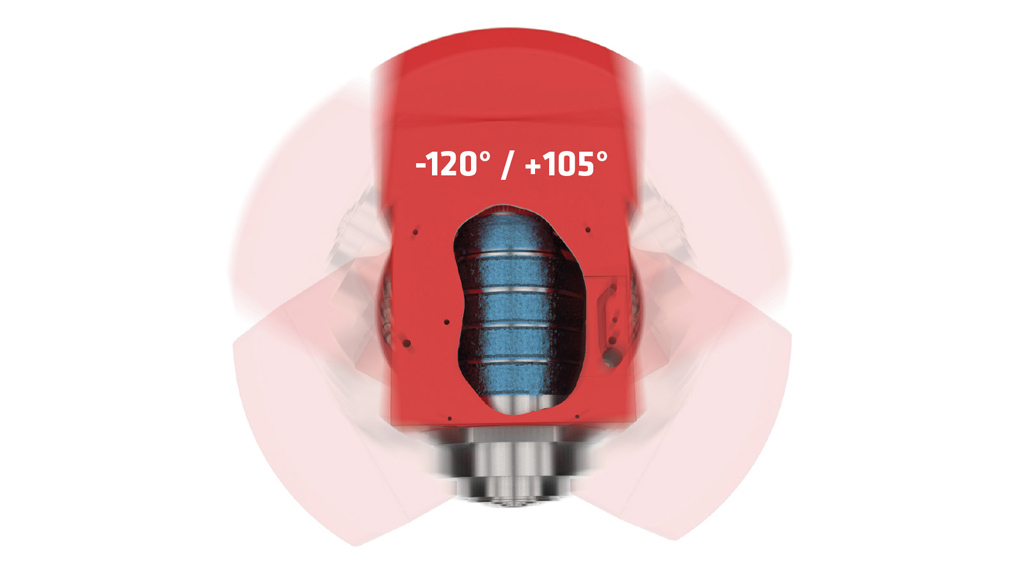

| B axis of tool spindle | |||||||||||

| Range | -120° / +120° | -120° / +120° | -120° / +120° | -120° / +120° | -120° / +120° | -120° / +120° | -120° / +120° | -120° / +120° | -120° / +120° | -120° / +120° | |

| Min. programming step | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | 0,0001° | |

| Max. speed | min-1 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Time of indexing by 90° | s | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 |

| Torque 40% ED / continuous | Nm | 1300 / 750 | 1300 / 750 | 1300 / 750 | 1300 / 750 | 1300 / 750 | 1300 / 750 | 1300 / 750 | 1300 / 750 | 1300 / 750 | 1300 / 750 |

| Hydraulic brake / locking | Nm | 8000 [1700 / 8200] | 8000 [1700 / 8200] | 8000 [1700 / 8200] | 8000 [1700 / 8200] | 8000 [1700 / 8200] | 8000 [1700 / 8200] | 8000 [1700 / 8200] | 8000 [1700 / 8200] | 8000 [1700 / 8200] | 8000 [1700 / 8200] |

| Tool magazine | |||||||||||

| Tool storage capacity | |||||||||||

| HSK-T63, Capto C6 | 66 [120; 180] | 66 [120; 180] | 66 [120; 180] | 66 [120; 180] | 66 [120; 180] | 66 [120; 180] | 66 [120; 180] | 66 [120; 180] | 66 [120; 180] | 66 [120; 180] | |

| HSK-100, Capto C8 | 44 [80; 120] | 44 [80; 120] | 44 [80; 120] | 44 [80; 120] | 44 [80; 120] | 44 [80; 120] | 44 [80; 120] | 44 [80; 120] | 44 [80; 120] | 44 [80; 120] | |

| Max. tool length | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| Max. tool diameter | |||||||||||

| With / without adjacent HSK-T63, Capto C6 | mm | 175 / 90 | 175 / 90 | 175 / 90 | 175 / 90 | 175 / 90 | 175 / 90 | 175 / 90 | 175 / 90 | 175 / 90 | 175 / 90 |

| With / without adjacent HSK-T100, Capto C8 | mm | 200 / 130 | 200 / 130 | 200 / 130 | 200 / 130 | 200 / 130 | 200 / 130 | 200 / 130 | 200 / 130 | 200 / 130 | 200 / 130 |

| Max. tool weight | kg | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Tool to tool / chip to chip change time | s | 03.okt | 03.okt | 03.okt | 03.okt | 03.okt | 03.okt | 03.okt | 03.okt | 03.okt | 03.okt |

| Tailstock | |||||||||||

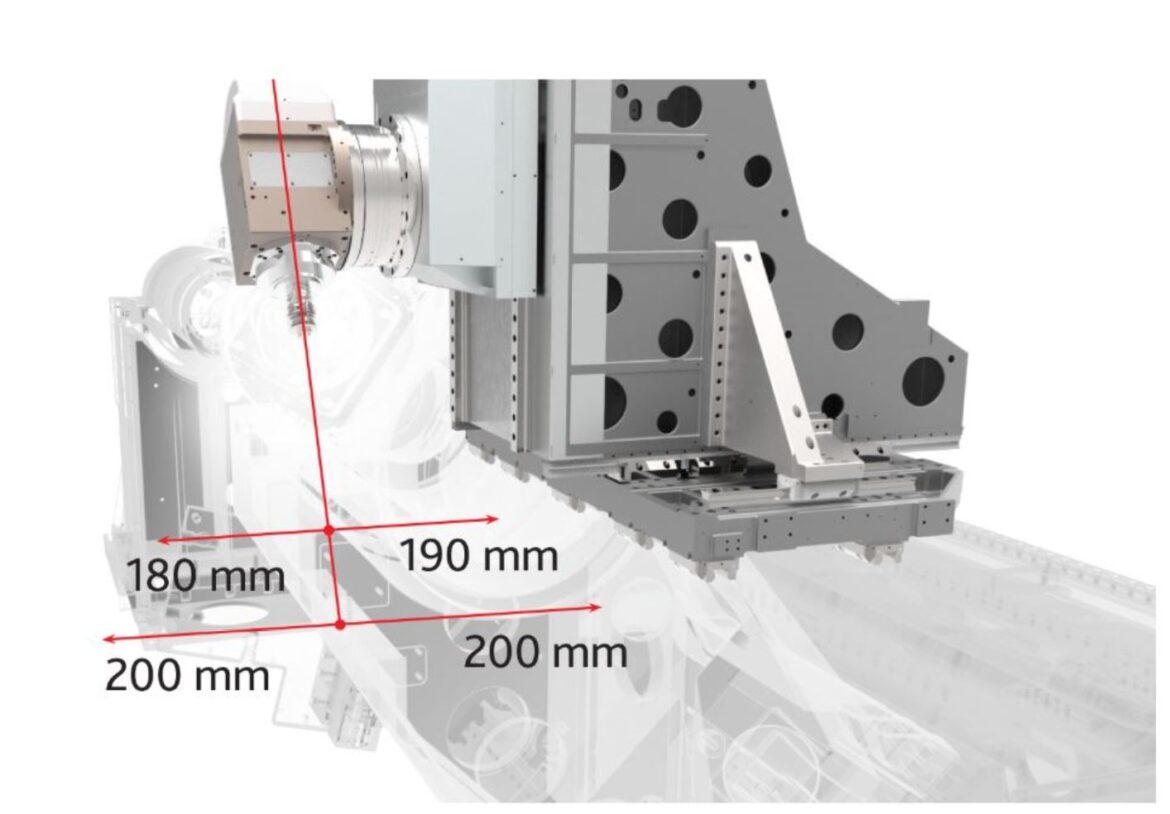

| Tailstock spindle diameter / Tailstock spindle travel | mm | 190 / 180 | – | 190 / 180 | – | 190 / 180 | – | 190 / 180 | – | 190 / 180 | – |

| Taper hole of tailstock spindle Morse | Mo6 | – | Mo6 | – | Mo6 | – | Mo6 | – | Mo6 | – | |

| Force range | kN | 2,5 – 25 | – | 2,5 – 25 | – | 2,5 – 25 | 2,5 – 25 | 2,5 – 25 | – | 2,5 – 25 | – |

| Coolant tank | |||||||||||

| Tank capacity / Coolant volume | l | 500 / 700 | 500 / 700 | 500 / 700 | 500 / 700 | 500 / 800 | 500 / 800 | 500 / 900; 500 / 1000 | 500 / 900; 500 / 1000 | 500 / 900; 500 / 1000 | 500 / 900; 500 / 1000 |

| Pump motor power continuous | kW | – | – | – | – | – | – | – | |||

| Machine dimensions | |||||||||||

| Machine length without / with chip conveyor / for transport | mm | 6630 / 7900 / 6630 | 6630 / 7900 / 6630 | 7130 / 8400 / 7130 | 7130 / 8400 / 7130 | 8130 / 9400 / 8130 | 8130 / 9400 / 8130 | 9630 / 10 900 / 9630 | 9630 / 10 900 / 9630 | 11 130 / 12 400 / 11 130 | 11 130 / 12 400 / 11 130 |

| Machine width / for transport | mm | 5150 / 3100 | 5150 / 3100 | 5150 / 3100 | 5150 / 3100 | 5150 / 3100 | 5150 / 3100 | 5150 / 3100 | 5150 / 3100 | 5150 / 3100 | 5150 / 3100 |

| Machine height / for transport | mm | 3100 / 3000 | 3100 / 3000 | 3100 / 3000 | 3100 / 3000 | 3100 / 3000 | 3100 / 3000 | 3100 / 3000 | 3100 / 3000 | 3100 / 3000 | 3100 / 3000 |

| Machine weight | kg | 24 000 | 24 000 | 25 000 | 25 000 | 26 500 | 26 500 | 28 500 | 28 500 | 30 000 | 30 000 |

| Machine connection | |||||||||||

| Eletrical power supply continuous | kVA | 100 | 150 | 150 | 150 | 100 | 150 | 100 | 125 | 100 | 125 |

| Compressed air supply pressure / flow | MPa/L.min-1 | 0,6 / 500 | 0,6 / 500 | 0,6 / 500 | 0,6 / 500 | 0,6 / 500 | 0,6 / 500 | 0,6 / 500 | 0,6 / 500 | 0,6 / 500 | 0,6 / 500 |

| Control system | |||||||||||

| Type | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | |

| Number of continuously controlled axes for machining | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |