CMS tecnocut waterspeedy s Complete Waterjet Cutting Systems

Quick and versatile cutting Waterjet robot, specifically designed for all flexible materials, such as plastics, rubbers, foams, composites, layered materials, industrial gaskets and technical materials. Its speed, the ability to use multiple cutting heads, and the automatic pallet change system offer high levels of productivity at very competitive costs compared to conventional systems.

Tecnocut Waterspeedy S is a system suitable for soft materials cutting as plastic, foams, rubbers, composites, multilayer materials, gaskets and technical materials. Its extremely high dynamic, together with the possibility to work with several cutting heads and its automatic pallet change system, assures very high productivity and competitive costs when compared to conventional systems. Tecnocut Waterspeedy S is the result of a careful design for the satisfaction of customer’s requirements and it tends to reach the highest safety standards.

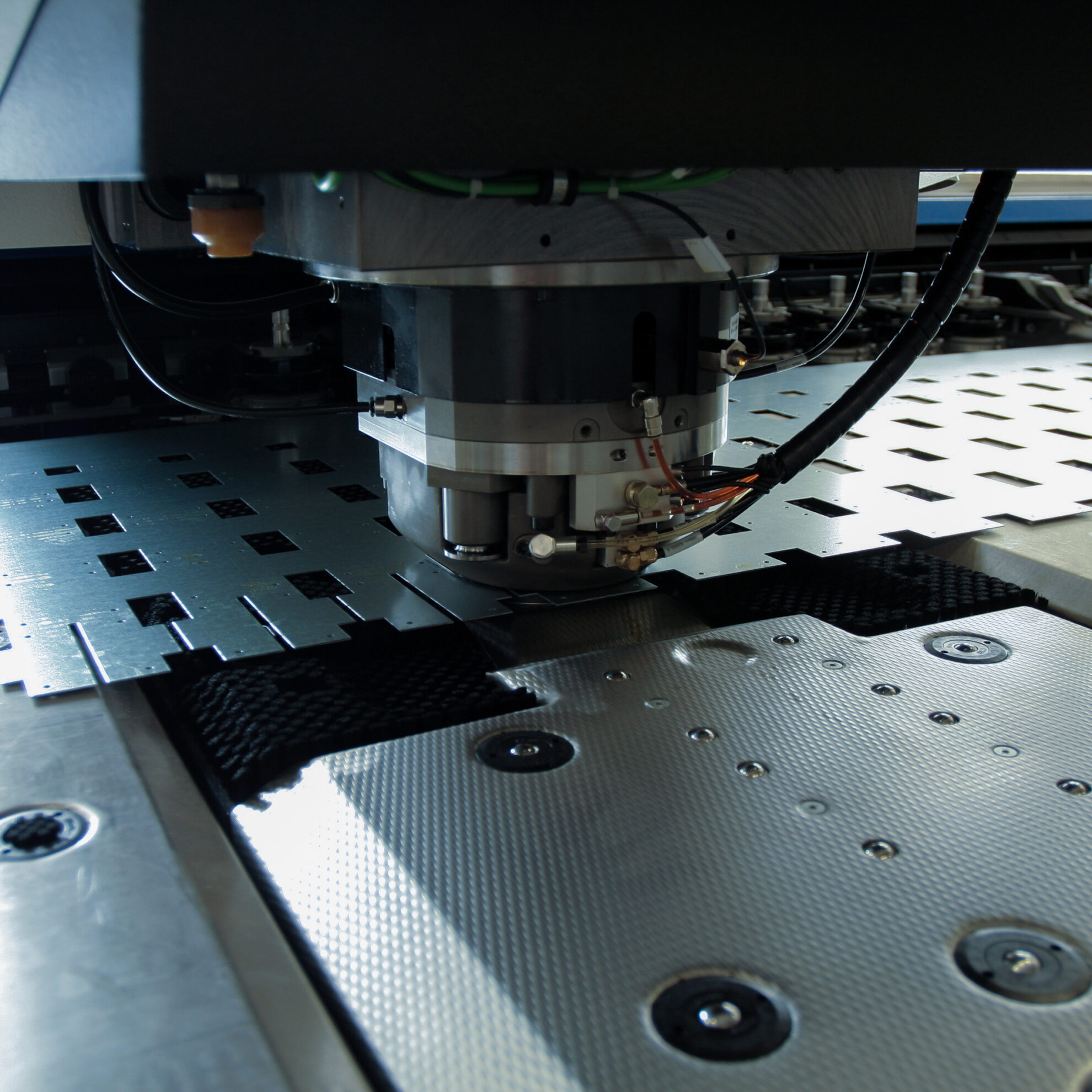

MOTION High precision and performance helical racks and pinions.

WORKTABLE Honeycomb stainless steel grid for plastic materials cutting. Optional: stainless steel net conveyor to cut roll material.

SAFETY CABIN Sound-proof closed cabin for the cutting area protection which prevents any contact with mechanical parts in motion and retains water and dust.

MULTIPLE HEADS Additonal pure waterjet cutting heads composed of trolleys with 3 or 5 heads with automatic distance adjustment to get high performances during the cutting process. Distance between heads is CNC controlled. Optional: double carriage for the highest productivity.

STEAM SUCTION Suction system for steam discharge with HEPA 99.997% absolute filter, positioned on the side of the machine.

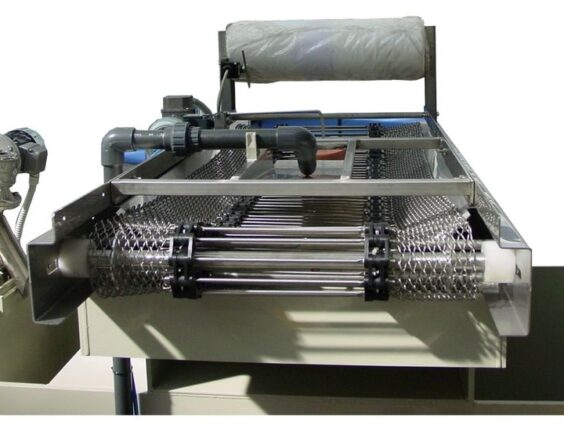

WASTE WATER FILTERING SYSTEM An automatic system leads scraps on the rear side of the machine where a paper filter with a collection tank cleans discharge water.

AUTOMATIC TANK CLEANING SYSTEM A set of nozzles inside the tank wash away the cutting debris to the external waste water filtering system.

| TECNOCUT WATERSPEEDY S 1630: TECHNICAL DATA | |

| X Axis | 3000 mm |

| Y Axis | 1600 mm |

| Z Axis | 200 mm |

| Worktable | 1630×3080 mm |

| Overall dimensions | 10150x4910x2800 mm |

| Support plane max capacity: 150 kg/mq | |

| Max speed: 2755.9 ipm | |

| PC panel with 21” LCD monitor, keyboard, mouse and manual control device | |

| External port for USB key interface | |

| Connection to the computer network: RJ45 10/100 Mb connector | |