Elektrinės lankstymo staklės AD-ES

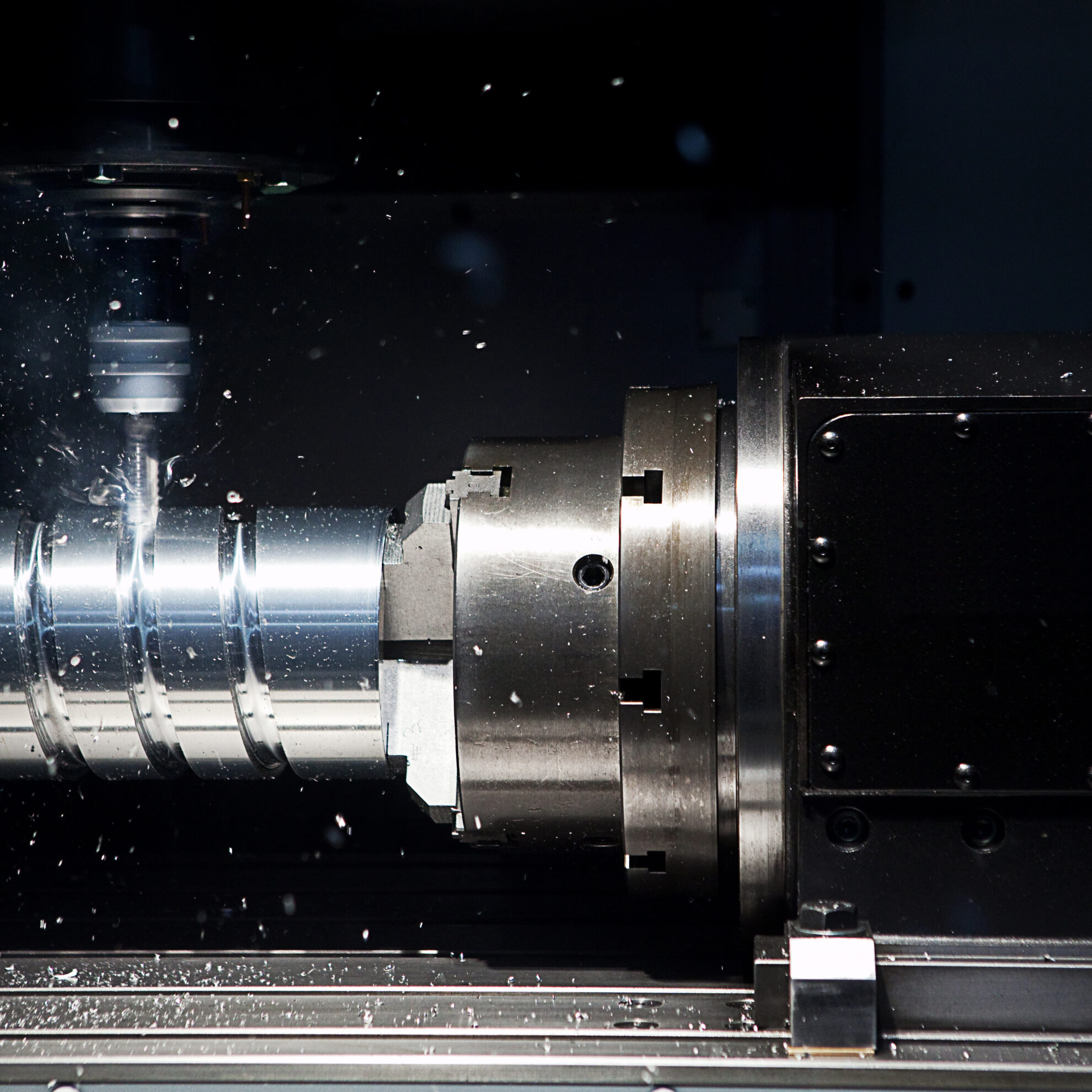

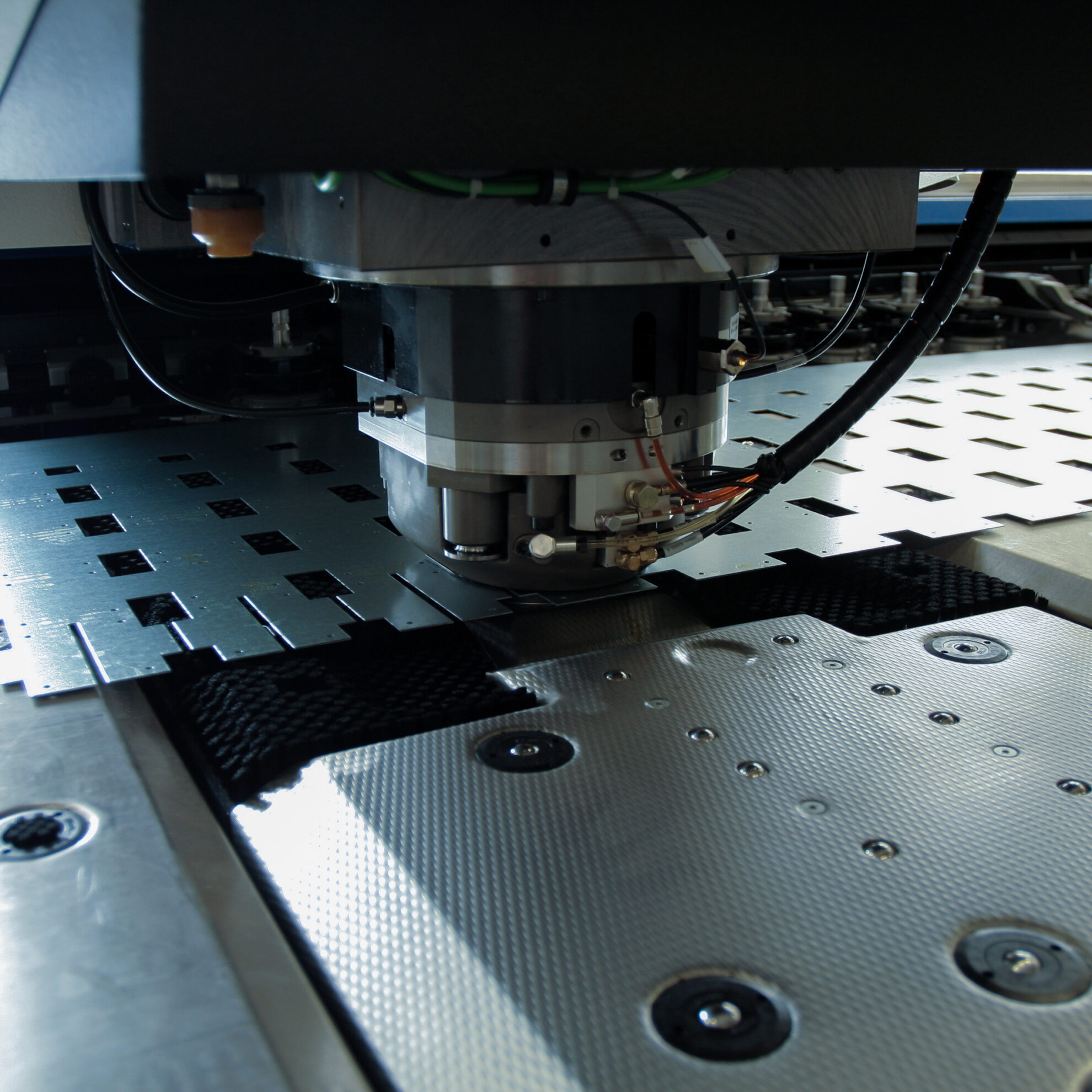

Ekologiškos „Durma” elektrinės skardos lankstymo staklės AD-ES yra įvairių dydžių. Darbo stalo plotis gali būti nuo 1250 mm iki 2500 mm. Staklės gali būti pritaikytos pagal kliento matmenis. Taip pat galimi skirtingi dydžiai pagal kliento reikalavimus. Mašinos rėmas yra suvirintas. Griežtos ir efektyvios apdirbimo technologijos leidžia išvengti per didelio atliekų kiekio. AD-ES elektrinių lenkimo staklių reduktoriaus pavaros sistema, tikslus sraigtinis velenas ir didelio sukimo momento tvirtas guolių cilindras užtikrina tikslius lenkimo rezultatus.

Kokie yra „Durma AD-ES” elektrinių lankstymo staklių privalumai?

Dėl lengvai naudojamo valdymo bloko, stabilios korpuso konstrukcijos, tobulos konstrukcijos, mažų eksploatavimo sąnaudų, plataus įrankių pasirinkimo ir maksimalių saugos standartų „Durma” lenkimo staklės yra geriausios pasaulyje savo segmente. Durma lenkimo staklės yra greitos, efektyvios ir modernios. Durma AD-ES elektrinės lenkimo staklės pasižymi šiomis savybėmis: aliumininėmis atraminėmis sistemomis, lakštų priekinėmis pastūmomis, tikslia hidraulika, Durma licencijuota viršutinio stalo slankiojimo sistema, Euro tipo perforatorių laikikliais, dideliu greičiu ir dideliu eigos ilgiu Y1-Y2 lenkimo ašimis ir CE saugos standartais.

Elektrinės lankstymo staklės „Durma AD-ES” sukurtos atsižvelgiant į efektyvumą ir aplinkos tausojimą. Ji užtikrina 17 proc. didesnį našumą ir sunaudoja 40 proc. mažiau energijos. Elektrinės lakštinio metalo lenkimo staklės AD-ES išsiskiria iš kitų savo tikslumu, dideliu našumu ir elegantišku dizainu. Jis buvo specialiai sukurtas taip, kad sunaudotų mažai energijos. Naujausia staklių technologija ir įranga – supaprastintas pavaros blokas. Mažiau komponentų leidžia lengvai ir greitai surinkti. Mašinos konstrukcija užtikrina lengvą valdymą ir priežiūrą.

Durma elektrinių lankstymo staklių AD-ES technologija

AD-ES lankstymo staklių įranga:

- Pilna diržų ir skriemulių sistema,

- Viršutinis darbo stalas, pritaikytas EURO/Wila tipo įrankiams,

- Tvirta rėmo konstrukcija, užtikrinanti ilgą tarnavimo laiką ir aukštą našumą,

- Saugesnei darbo aplinkai,

- Servo varikliai, užtikrinantys didelį greitį ir tikslumą,

- Rutulinis sraigtas ir veržlės jungtis puikiai perduoda galią ir judesį,

- Tvirta galinės atramos sistema ir standus aliuminio AP1-AP2 rėmas, didelis mobilumas ir aliuminio narvelių sistema,

- CE saugos standartai.

Valdymo blokas – DA-69T 3D jutiklinis ekranas

Y1, Y2, X, R (4 ašys) X=650 mm balnelis (Al – dviguba kreipiančioji)

CE motorizuotas FIESSLER AKAS-3 M + FPSC (su saugos PLC)

DBEND 3D lenkimo paruošimo ir modeliavimo programinė įranga

Servoelektriniu varikliu valdomas balnas, linijinė kreipiančioji, rutulinių sraigtų sistema (X-R).

Motorizuotas bombardavimas, valdomas skaitmeninio valdymo įrenginio

Europinio tipo įrankių laikymo sistema

Stumdomieji laikikliai – stumdomieji laikikliai slenka ant viso ilgio linijinių šliaužiklių su T profiliu ir fiksavimo mechanizmu

| AD-ES serijos techninė informacija | |||||||||||||||

| Mašinų tipai | Lenkimo galia | Lenkimo ilgis | Atstumas tarp stulpelių | Apsilankykite | Didžiausias nuotolis (D) | Darbinis aukštis (F) | Artėjimo greitis | Lenkimo greitis | Sukimosi greitis | Atgalinis matuoklis X ašis Ilgis | Atgalinis matuoklis R ašis Ilgis | Ilgis | Plotis | Aukštis | Svoris |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vienetas | Ton | mm | mm | mm | mm | mm | mm/sn | mm/sn | mm/sn | mm | mm | mm | mm | mm | kg |

| AD-ES 1240 | 40 | 1250 | 1300 | 200 | 440 | 1000 | 120-180 | 20-40* | 120-180 | 650 | 250 | 2150 | 1625 | 2800 | 4500 |

| AD-ES 2040 | 40 | 2050 | 2050 | 200 | 440 | 1000 | 120-180 | 20-40* | 120-180 | 650 | 250 | 2870 | 1625 | 2800 | 5600 |

| AD-ES 2560 | 60 | 2550 | 2550 | 200 | 400 | 1000 | 120-180 | 20-40* | 120-180 | 650 | 250 | 3370 | 1875 | 3200 | 6600 |

| * Pagal CE normą lenkimo greitis turi būti ne didesnis kaip 10 mm/s, išskyrus robotus. | |||||||||||||||

Valdymo blokas – DELEM-66T

Valdymo blokas – CNC ModEva19T

Z1, Z2 ašys

CE vadovas F.AKAS II M -FPSC-B-C Apsauga nuo šviesos (su apsaugos PLC)

X=650mm X,R,Z1,Z2,Delta X +/- 125mm CNC valdomas (AL)

X ašis = 1000 mm – Galinė apsauga su šviesos barjerais

Lazerinė kampo matavimo sistema

Greito tvirtinimo sistema

Hidraulinė ir pneumatinė įrankių laikymo sistema

Viršutinis ir apatinis įrankis

Centrinė tepimo sistema

Papildomas atraminis pirštas ir papildoma slankiojanti priekinė skardos atramos sistema

Speciali pakuotė užsienio šalims