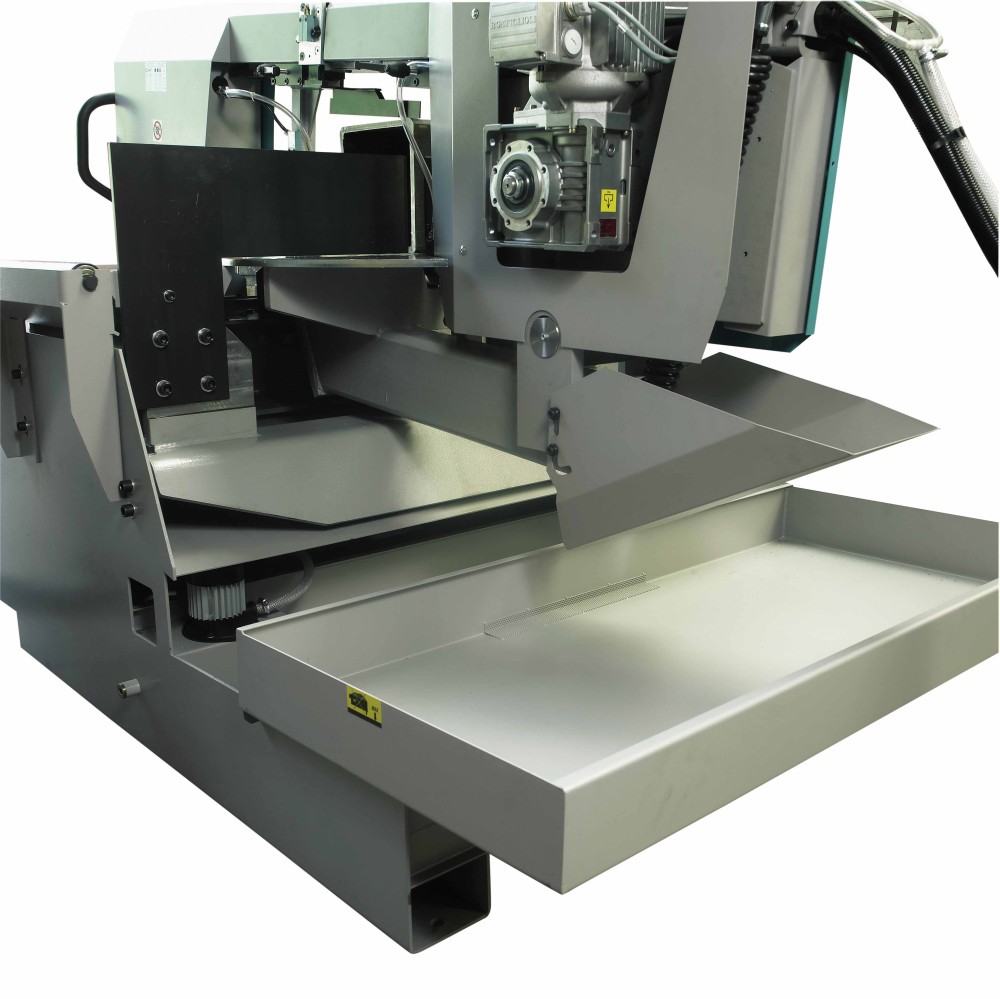

IMET H 601 Semiautomatic twin column bandsaw

Semiautomatic twin column bandsaw, hydraulically driven. Especially adapt to cut sections of steelwork, tubes and solids.

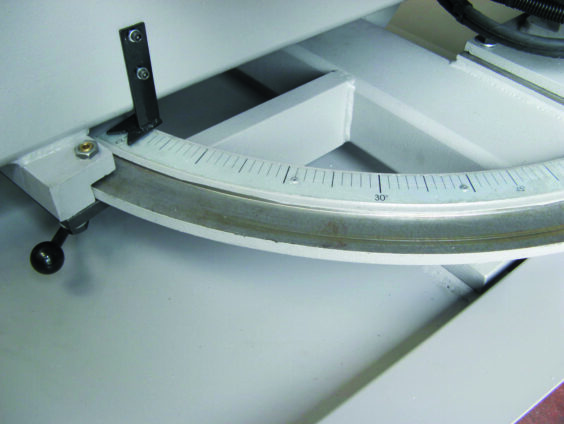

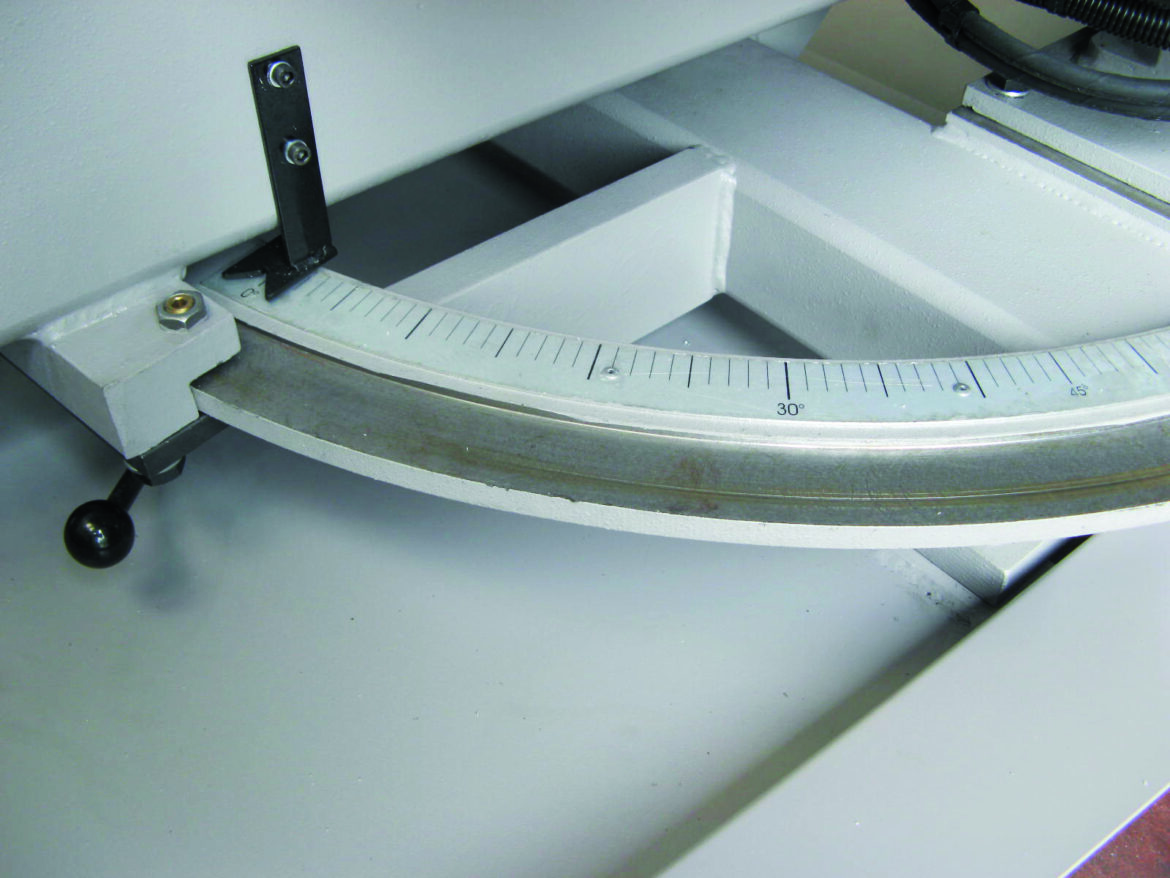

Possibility to make cuts with variable angle up to 60° to the left, with the manual shifting of the saw frame.

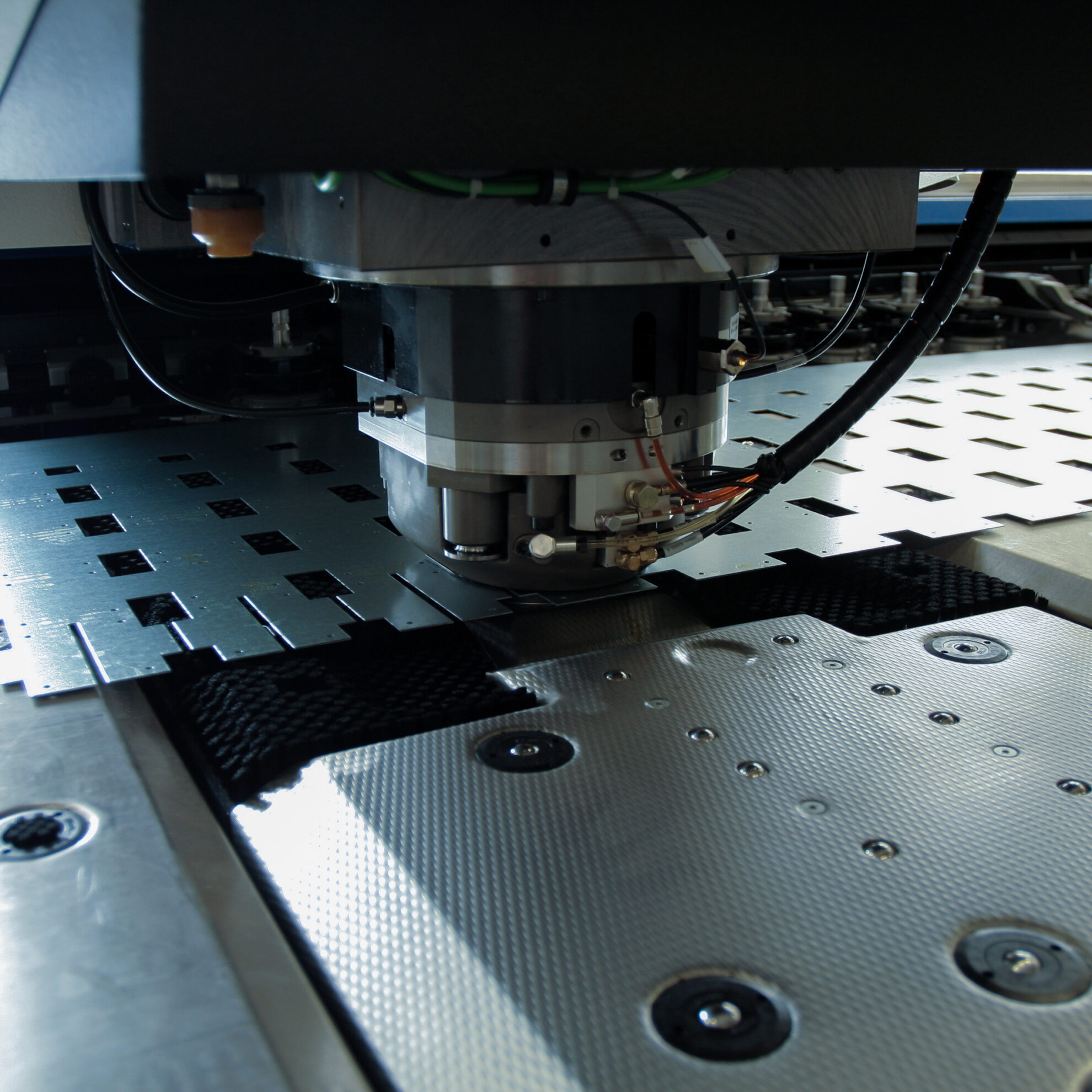

Steel sawframe with tubular section; worktable supported by a central pivot with preloaded bearings.

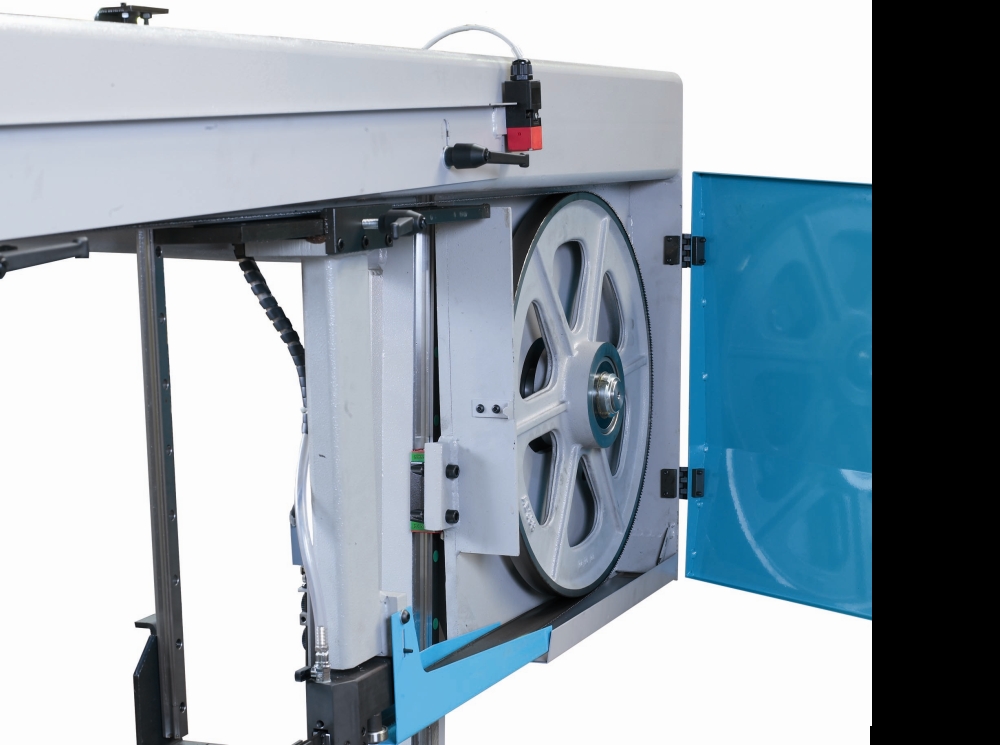

Sawframe movement onto an electro welded column of big dimension, through two recirculating ballscrews linear guides.

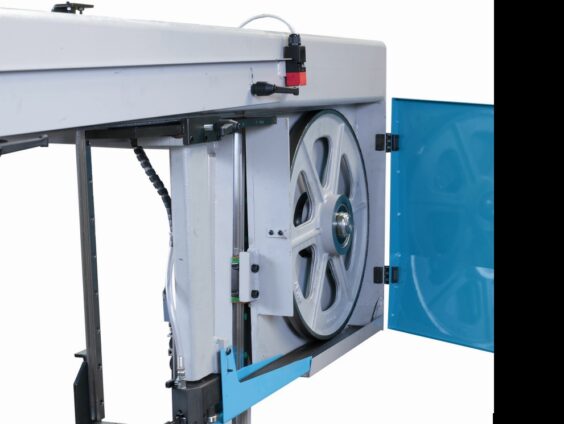

Pulley diameter 520 mm. Long-Life monobloc motoreducer.

Registrable band guides with hard metal pads and guided bearings.

Electronic Inverter for variable blade speed.

Automatic control of the beginning and end cut through a feeler pin; regulation of the descent of the arc and strength of the penetration through the console.

Mechanical tensioning of the blade with a control micro switch.

Sawframe canted 6° allows sawblade to freely and easily cut through the bottom of structural section without vibration, binding, or slowdown of sawing rates.

Cutting capacity at 90 °, round till 120 mm., square till 100 mm., rectangular till 180×100 mm.

| H 601 | ||

| Area angular cut | ° | 90 / +30 |

| Cutting capacity at 90°: round / square / rectangular | mm. | 500 / 450 / 610 x 440 |

| Cutting capacity at 90°: rectangular with cutting bundle | mm. | 600 x 250 max 150 x 50 min |

| Blade dimensions | mm. | 5320 x 34 x 1.1 or on request 5320 x 41 x 1.3 |

| Blade Motor Power | KW | 3 or on request 4 |

| Blade speed | mt/min. | 15÷100 |

| Motor hydraulic unit | KW | 0.75 |

| Tank Capacity of the hydraulic unit | Lt | 20 |

| Capacity coolant tank | Lt | 60 |

| Dimensions ( B x L x H ) | mm. | 1500 x 2850 x 2170 |

| Height fo the work-table | mm. | 820 |

| Weight | Kg | 1700 |

| Type of functioning | Semiautomatic hydraulic | |

| Suitable for cutting: | Steel / cast iron / high-strength steels / alloys | |